The Advance of Heat Shrink Film Packaging Machine

2023-09-19 09:47

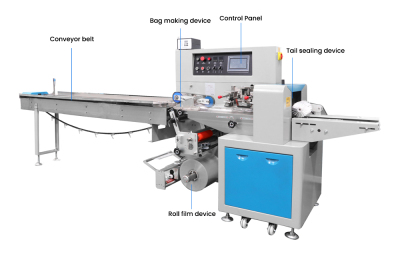

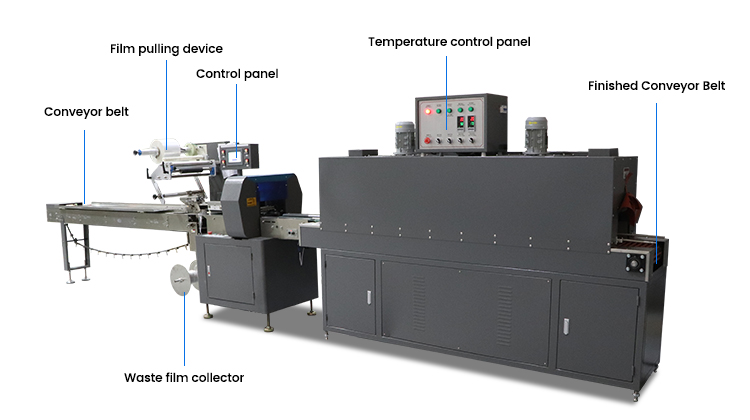

The heat shrink packaging machine uses shrink film to wrap the product on the outside. After heating, the shrink film shrinks and tightly wraps the product, which can better display the appearance of the product, improve the display performance of the product, and increase the aesthetics and value of the product. The main structure of this machine can be divided into seven parts. It consists of a conveyor belt, film pulling device, bag making machine, heat sealing cutter, control panel, temperature controller and heat shrink furnace.

There are two types of conveyor belts, one is a belt conveyor suitable for long materials and the other is a pusher with a fixed length and therefore suitable for short products. The width of both conveyor belts can be adjusted according to the size of the material. In addition, next to the conveyor switch is a speed regulator that can be used to adjust the speed of the conveyor belt.

We have improved the conveyor belt where the bag making machine is located and transformed it into a belt, making the contact surface larger and more stable during product transmission. The bag making machine is adjustable and can adjust the height and size according to the product.

An optional device is located between the conveyor belt and the bag making machine, before the material enters the bag making machine. For example, sensing devices, such as radio eyes, can recognize the length of the material, and the sensitivity of the radio eye is also adjustable. This position can also be equipped with a blowing nozzle, which is used to adjust the size of the blowing according to on-site conditions to assist in the contraction effect.

There are other optional devices, such as a punching device, installed near the separation axis. The function of this device is to let the air inside out during contraction to achieve better contraction effect.

The operation process is: put the material on the conveyor belt, pass through the bag making machine, the middle sealing area and the end sealing area to complete the preliminary packaging of the material, and then come out of the heat shrinking furnace to achieve the heat shrinkage effect, which is the final product. details make a difference. Of course, in the middle seal area, we use sponge middle seal material and belt drive, which can help better material transfer while exhausting. Additionally, it is finely tuned to meet the needs of our customers' products. From the end sealing area, the knife holder is heat-sealed, and the height of the knife holder can be selected according to the height of the product. End seal transportation adopts drag chain type, which can help products transition better and avoid getting stuck in the connection gap of the device.

Use a heat shrink packaging machine to package products to achieve moisture-proof, dust-proof, and waterproof purposes, and at the same time, make the product look very beautiful and elegant. This is your best choice, choosing us is a wise move.

Get the latest price? We'll respond as soon as possible(within 12 hours)