How to choose vegetable wrapping machine

2023-09-21 08:33

Today is the Internet age. The rise of e-commerce platforms has changed the lifestyles of countless producers and sellers. Many operators choose to transform from traditional production to mechanized production, and from traditional physical operations to online e-commerce operations. Product packaging mode has also changed from traditional manual packaging to mechanized packaging.

Let us compare the characteristics and differences between traditional manual packaging and mechanized packaging, as shown below.

1. Characteristics of traditional manual packaging:

High cost: Currently, labor costs are rising and time costs are very high.

Inefficiency: Difficulty recruiting, retaining, and replacing ineffective new personnel.

Environmental Issues: Health issues in the workplace are difficult to manage.

Packaging accuracy: Manual packaging accuracy is unstable.

2. Advantages of packaging mechanization:

Labor cost: Packaging machinery can work 24 hours a day and can withstand high working pressure.

High work efficiency: The automatic packaging machine is fast and efficient, which is unmatched by manual work.

Hygiene and energy saving: the packaging process is clean and hygienic.

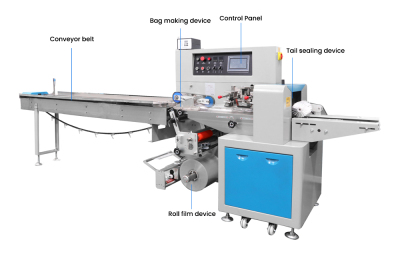

The operation is convenient and fast, and multiple processes can be completed at one time: automatic bag making, coding, labeling, packaging, sealing, etc.

3. How to choose a suitable vegetable packaging machine?

3.1 First of all, you must know what your target sales model is, such as supermarket, door-to-door delivery, APP delivery, store, logistics delivery, restaurant delivery, market wholesale, etc.

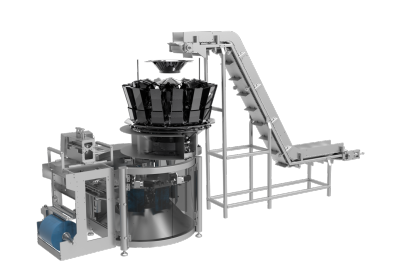

3.2 If used in supermarkets, the weight of general supermarket bags is between 300-1000 grams, so you can choose the 330X model. The maximum width of the film is up to 680mm and the maximum width of the bag is 330mm.

3.3 If the packaged vegetables are between 300-500 grams, we recommend using a 280X servo machine. The maximum bag width can reach 280 mm.

3.4 If the packaged vegetables are within 1KG, the 330X model can be recommended.

3.5 It is recommended that pneumatic equipment be used for 1-2.5KG logistics restaurant delivery. We have done a case where the customer packed a 2.5 kilogram bag of vegetables. Bag size is L500*W400mm, height is 150mm.

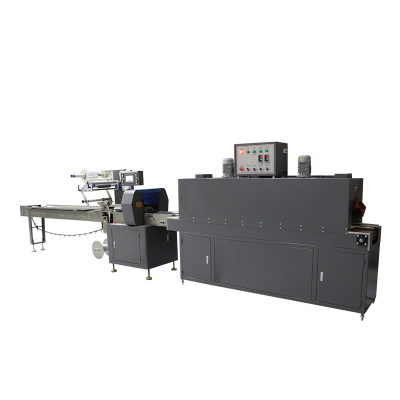

3.6 If you need to package various vegetables, the pneumatic servo packaging machine is the best choice.

Since the pneumatic servo packaging machine can automatically identify the length of the product, and then the machine can automatically set the length of the bag based on the signal from the sensor, one machine can package products of different lengths at the same time. It increases efficiency and saves costs.

4. Optional configuration:

4.1 Packaging film punching and exhaust device: It is divided into electric punching and pneumatic punching, which helps to discharge the air in the bag and save space for long-distance transportation.

4.2 Nitrogen filling device: Use high-purity nitrogen to fill bagged vegetables and fruits with nitrogen, which can extend the shelf life.

4.3 Weighing and labeling device: After the vegetable bags are packed, each bag will be automatically weighed, and then the computer will automatically print out a note and automatically paste the corresponding vegetable bag label, which is very suitable for supermarket sales.

Get the latest price? We'll respond as soon as possible(within 12 hours)