Introduction to Bag Making and Bag Feeding Machine

2024-01-15 14:38

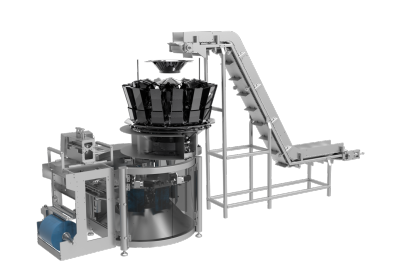

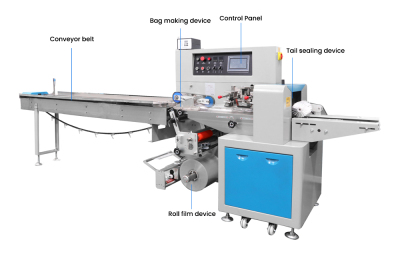

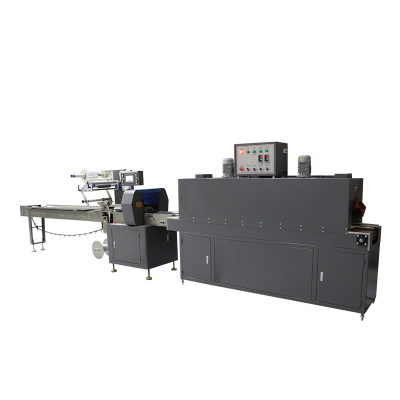

Bag making and feeding packing machine is a type of packaging machinery equipment mainly used for making various plastic packaging bags or other material packaging bags. This equipment usually consists of a bag feeder and a weighing machine, where the weighing machine can be weighing or screw type, suitable for packaging particles and powder materials.

The working principle of the bag making and feeding machine is to use a robotic arm to pick up, open, set and seal the user's prefabricated bags. At the same time, under the coordinated control of a microcomputer, it completes functions such as filling and coding, thereby achieving automated packaging of prefabricated bags. The characteristic of this device is that the robotic arm replaces manual bagging, which can effectively reduce bacterial contamination in the packaging process and improve the level of automation. It is suitable for small-scale and large-scale automated packaging of food, seasoning and other products.

The basic characteristics of a bag making and feeding machine include:

1. High degree of automation can effectively reduce manual operations and improve production efficiency.

2. The packaging range is wide and can be applied to the packaging of materials such as liquids, sauces, particles, powders, irregular blocks, etc.

3. Packaging bags have a wide range of applications, including prefabricated bags and paper bags made of multi-layer composite films, silica, aluminum foil, single-layer PE, PP, and other materials.

4. Easy to operate, with automatic quantitative weighing function. The load capacity of the weighing unit is automatically optimized and combined through the PLC system using the principle of arrangement and combination, and the weight combination closest to the target weight value is obtained for packaging.

5. The equipment has stable and reliable performance, and can work continuously and efficiently.

The equipment is expensive, but long-term use can save a lot of labor costs.

Get the latest price? We'll respond as soon as possible(within 12 hours)