New Machine: Introduction to Full Servo Vertical Packaging Machine

The full servo vertical packaging machine is a modern packaging equipment that integrates efficiency, accuracy, diversity, and reliability. It fully utilizes the advantages of servo drive control systems to convert electrical signals into mechanical rotation, achieving precise control of various actions of the packaging machine.

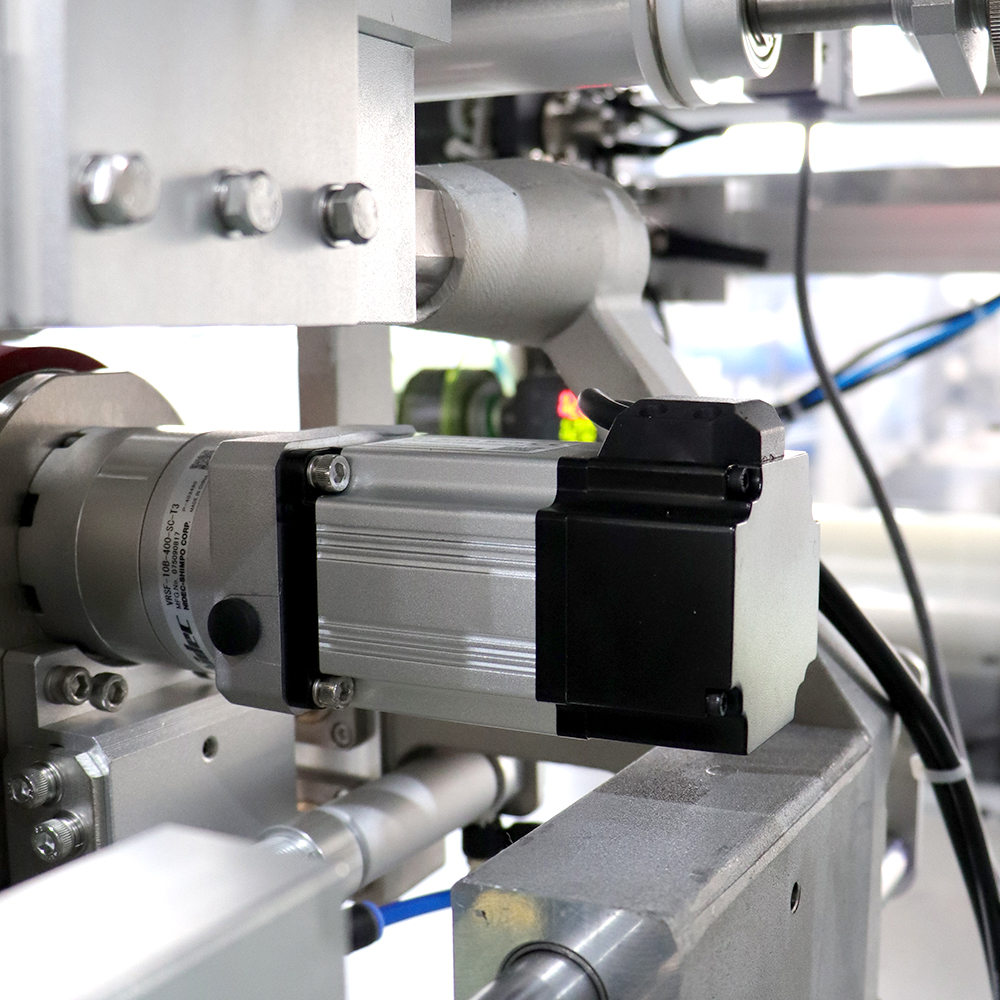

Structurally, the full servo vertical packaging machine adopts a servo motor as the main driving component for the traction structure and horizontal sealing. This design makes the positioning accuracy high, easy to adjust, and the pressure and opening stroke can be adjusted at any time, making the sealing tight and airtight. In addition, it is equipped with inflation and exhaust devices, as well as the ability to replace the filling machine head to meet the needs of various materials.

In terms of performance, the full servo vertical packaging machine has significant advantages. Its efficiency can meet the large packaging needs of the production line, achieving more efficient operation and higher output. Meanwhile, the high-precision measurement system ensures that the packaging weight of each bag of products meets quality standards. It is suitable for products of various shapes and sizes, including food, health products, hardware and plastics, construction to cosmetics, etc.

In terms of performance, the full servo vertical packaging machine has significant advantages. Its efficiency can meet the large packaging needs of the production line, achieving more efficient operation and higher output. Meanwhile, the high-precision measurement system ensures that the packaging weight of each bag of products meets quality standards. It is suitable for products of various shapes and sizes, including food, health products, hardware and plastics, construction to cosmetics, etc.

In terms of intelligence, the full servo vertical packaging machine is combined with touch screens, PLC and other control systems to form a complete packaging production line control system. This not only improves the control accuracy, speed range, and reliability of the entire machine, but also significantly simplifies the mechanical transmission system, reducing mechanical noise and failure rates. In addition, an intelligent operating system makes device operation simple and easy to use, reduces the skill requirements for operators, and also reduces usage costs.

Get the latest price? We'll respond as soon as possible(within 12 hours)