Capsule & Tablet Doypack Packaging Solution: Accurate Counting and Efficient Bag Filling

Capsule & Tablet Doypack Packaging Solution: Accurate Counting and Efficient Bag Filling

In the pharmaceutical and nutraceutical industries, packaging precision and cleanliness are essential for product safety, regulatory compliance, and consumer trust. Capsules and tablets, whether sold as over-the-counter supplements or prescription medications, must be packaged in accurate quantities and in tamper-proof, hygienic formats. The integrated capsule and tablet packaging solution—featuring an elevator, electronic counting machine, and rotary doypack machine—provides a fully automated system that ensures accurate counting, consistent bag filling, and secure sealing. This article outlines the key features, working process, and broad applications of this packaging system, showcasing its value for companies producing capsules, tablets, and similar solid-dose products.

Key Features

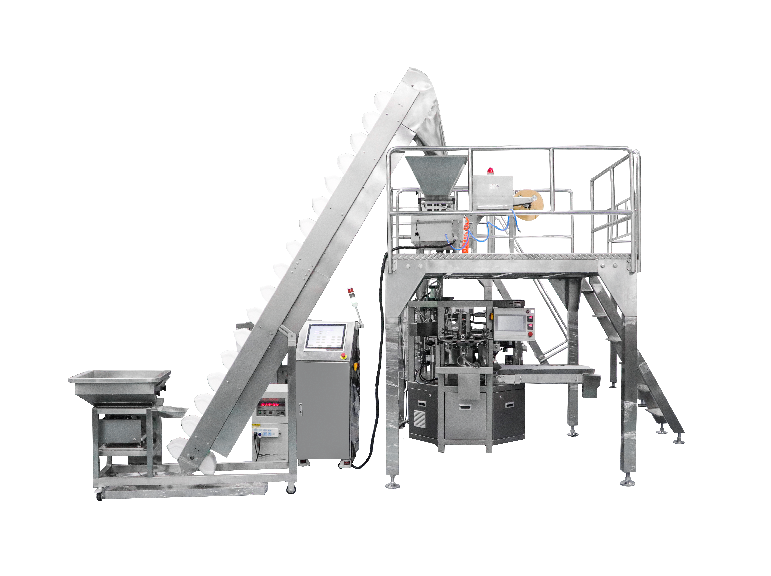

This integrated packaging line is composed of three main components: a Z-type elevator, a high-precision electronic counting machine, and a rotary doypack (pre-made pouch) packaging machine.

Elevator: Gently lifts capsules or tablets from the storage hopper to the counting system. Designed for hygienic operation, it minimizes dust and product damage.

Electronic Counting Machine: Uses multi-channel counting lanes and optical sensors to count capsules or tablets accurately. Advanced software algorithms ensure each pouch receives the correct quantity, preventing underfill or overfill.

Rotary Doypack Packaging Machine: Handles various pouch styles, including stand-up pouches, zipper bags, and flat pouches. Performs automatic pouch pickup, opening, filling, sealing, and printing. Optional features like nitrogen flushing or tear notches can be added for extended shelf life or consumer convenience.

This compact and automated setup minimizes human contact, improves efficiency, and maintains pharmaceutical-grade hygiene throughout the packaging process.

Working Principle of the Packaging System

1. Product Feeding: Capsules or tablets are loaded into the elevator hopper. The Z-type elevator gently conveys the product upward to the counting machine.

2. Accurate Counting: The electronic counting machine detects and counts each capsule/tablet using photoelectric sensors. Counted doses are grouped and prepared for dispensing.

3. Bag Preparation: The rotary doypack machine picks up a pre-made pouch, opens it, and positions it for filling.

4. Filling and Sealing: The counted capsules/tablets are dropped into the pouch. The machine then seals the pouch securely, maintaining product integrity.

5. Finished Output: Completed pouches are discharged for further packing, inspection, or boxing.

Applications: Beyond Capsules and Tablets

While the system is primarily designed for capsule and tablet packaging, its flexibility allows it to handle a wide variety of similar small solid items:

Softgel Capsules: Accurate portioning with gentle handling to prevent breakage.

Chewable Tablets & Gummy Supplements: Hygienic and consistent packaging for health products.

Hard Candies & Lozenges: Ideal for confectionery or medicated products.

Effervescent Tablets: Protective packaging that supports moisture barrier requirements.

Advantages of the Doypack Capsule Packaging System

1. Precise Counting: Optical sensors and smart algorithms ensure every pouch contains exactly the intended count, supporting regulatory and quality standards.

2. Hygienic and Compliant Design: All contact parts are made from food/pharma-grade stainless steel, compliant with GMP and CE/FDA standards.

3. Flexible Packaging Options: Compatible with various pre-made pouch formats, sizes, and features (resealable zippers, euro holes, printed designs).

4. High Efficiency and Low Labor Cost: Fully automated from feeding to sealing, reducing the need for manual handling and supervision.

5. Modular & Customizable: System can be customized with auxiliary equipment like metal detectors, checkweighers, or dehumidifiers to match specific production needs.

Conclusion

For pharmaceutical, supplement, and health product manufacturers, investing in a capsule and tablet doypack packaging system delivers clear benefits: accuracy, hygiene, speed, and flexibility. The integration of an elevator, counting machine, and rotary pouch packer ensures every package meets quality standards while maintaining operational efficiency.

Whether you're packaging capsules for retail sale or tablets for clinical use, this advanced packaging solution helps streamline production, improve product consistency, and elevate brand trust.

Get the latest price? We'll respond as soon as possible(within 12 hours)