Rice Vertical Packaging Machine: Accurate, Efficient, and Automated Grain Packing Solution

Rice Vertical Packaging Machine: Accurate, Efficient, and Automated Grain Packing Solution

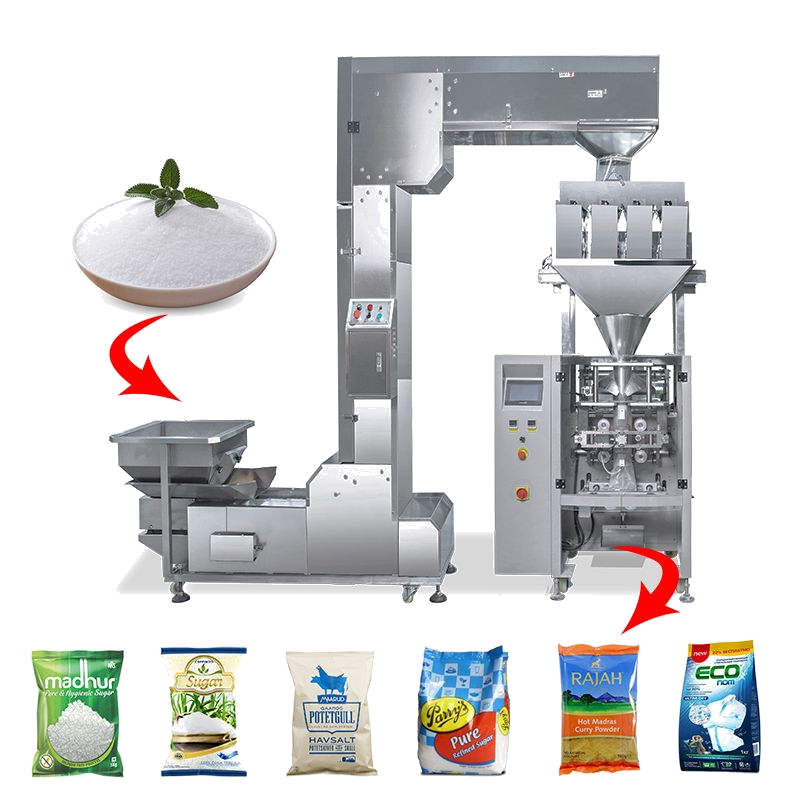

As one of the most consumed staple foods globally, rice demands a packaging process that is not only fast and efficient but also precise and contamination-free. Our vertical packaging solution—featuring a vertical form-fill-seal machine, 4-head linear weigher, and Z-type bucket elevator—offers an automated, high-accuracy system tailored specifically for granular products like rice. This article introduces the components, working principle, and key benefits of this integrated packaging system, designed to boost productivity while ensuring consistent packaging quality.

Key Features

1. 4-Head Linear Weigher Precision

Utilizes high-precision sensors and intelligent algorithms for stable and accurate weight control.

Ideal for free-flowing granules like white rice, jasmine rice, and parboiled rice.

Adjustable parameters allow for various target weights and packaging sizes.

2. Vertical Form-Fill-Seal Machine (VFFS)

Forms, fills, and seals packaging film into pouches such as pillow bags or gusseted bags.

Compact and efficient layout ensures space-saving operation.

Equipped with servo-driven film pulling and temperature-controlled sealing for reliable results.

3. Z-Type Bucket Elevator

Transports rice from the hopper to the weighing system with minimal spillage or damage.

Ensures consistent product feeding and avoids production interruptions.

Made of food-grade materials, easy to clean and maintain.

4. Hygienic Design & Durable Construction

All product contact parts made from SUS304 stainless steel, complying with food safety standards.

Fully enclosed structure reduces dust and contamination risks.

5. Smart Control System

PLC + HMI touchscreen interface enables easy setup, multi-recipe storage, and real-time error alerts.

Intuitive operation suitable for both new and experienced operators.

Working Principle

Working Principle

The rice packaging system operates in a streamlined automated process:

1. Product Feeding

Rice is loaded into the hopper and lifted by the Z-type elevator to the 4-head linear weigher.

2. Weighing Process

The linear weigher dispenses precisely measured amounts of rice, ensuring accurate filling and minimal waste.

3. Pouch Formation & Filling

The vertical machine forms pouches from a film roll. The weighed rice is dropped into the formed pouch.

4. Sealing & Cutting

Heat sealing jaws seal the pouch tightly, after which the finished pack is cut and discharged.

5. Final Output

Finished rice packs are ready for boxing, storage, or retail distribution

Application Scenarios

This packaging system is widely used for:

White rice (short-grain, long-grain)

Basmati rice

Parboiled rice

Organic rice

Mixed grains or pulses

It is ideal for rice mills, food packaging companies, supermarkets’ own-brand packing operations, and agricultural product processors.

Advantages of the Rice Vertical Packaging Line

High Accuracy: Linear weigher ensures each bag is consistent in weight, reducing giveaway.

High Efficiency: Fully automatic process greatly boosts productivity and reduces manual labor.

Flexibility: Supports various bag sizes from 500g to 5kg or more.

Clean & Reliable: Dust-free and food-grade operation meets international safety requirements.

Cost-Effective: Reduced material waste and energy-efficient components lower production costs.

Conclusion

If your business handles rice or similar granular food products, this vertical packaging system offers a robust and professional solution. With its combination of precision, speed, and automation, it helps manufacturers stay competitive in today’s fast-paced food market while ensuring consistent product presentation and consumer satisfaction.

Get the latest price? We'll respond as soon as possible(within 12 hours)