Robotic Carton Erector: Automated Solution for High-Efficiency Case Forming

Robotic Carton Erector: Automated Solution for High-Efficiency Case Forming

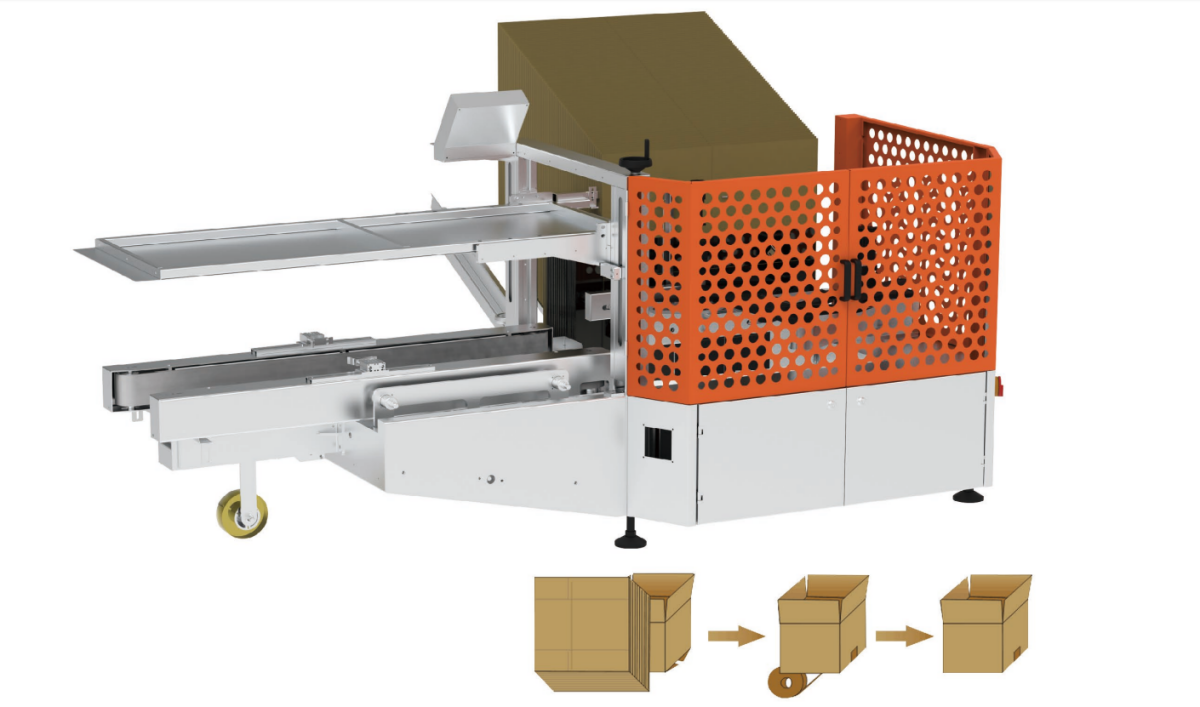

In modern packaging lines, automation is key to reducing labor costs, increasing productivity, and ensuring consistent quality. The robotic carton erector, also known as a mechanical arm case opener, is an advanced automatic machine designed to efficiently erect, fold, and seal corrugated cartons. It replaces manual case forming and offers higher speed, greater precision, and better integration with downstream packing systems. This article explores the features, working principle, and benefits of using a robotic carton erector in industrial and commercial packaging operations.

Key Features

The robotic carton erector utilizes a robotic arm or servo-controlled mechanical system to pick, open, and secure cartons from a flat-packed state to a fully formed box. It is ideal for industries requiring fast, repeatable, and low-error case forming.

Automated Carton Picking and Forming: Using suction cups or mechanical grippers, the machine accurately picks a flat carton from the magazine, opens it, and folds the bottom flaps.

Integrated Bottom Sealing: The machine applies adhesive tape or hot melt glue to seal the bottom flaps, ensuring stability before the box moves to the filling section.

Servo Motor and PLC Control: Advanced servo systems and PLC ensure precise movements and reliable performance. Touchscreen interface allows for easy operation and format changes.

Adjustable for Different Box Sizes: Supports quick adjustments to accommodate various carton dimensions, ideal for multi-product packaging lines.

Compact Footprint with Modular Design: The machine is compact and modular, making it easy to integrate into existing production lines.

Working Principle of the Robotic Carton Erector

1. Carton Loading: Flat cartons are stacked in the magazine. The system detects when to initiate the forming process.

2. Robotic Arm Pick-Up: A robotic arm with suction cups or mechanical grippers retrieves one carton at a time.

3. Carton Opening: The arm opens the carton and positions it for flap folding. Guiding mechanisms ensure the box is held squarely.

4. Bottom Flap Folding & Sealing: The machine folds the bottom flaps and applies adhesive tape or glue to seal the box securely.

5. Output to Next Station: The erected and sealed carton is transferred to the filling or packing section for product insertion.

Applications Across Industries

Robotic carton erectors are widely used in various industries requiring high-volume secondary packaging, such as:

Food & Beverage: For bottles, pouches, cans, or boxed products.

Pharmaceuticals: For medicine boxes and medical supplies.

Consumer Goods: For personal care products, electronics, toys, and hardware.

E-commerce & Logistics: For rapid fulfillment and standard-size box forming.

Household & Cleaning Products: For detergents, paper products, and more.

Advantages of Robotic Carton Erectors

1.Labor Cost Reduction: Automates the manual box forming process, reducing the need for workers and improving consistency.

2.High Speed and Stability: Capable of forming up to 5–30 cartons per minute with minimal error or stoppages.

3.Precision and Reliability: Robotic arm ensures exact placement and folding every time, reducing waste due to misaligned boxes.

4.Easy Operation and Maintenance: User-friendly interface and intuitive controls enable fast training and minimal downtime.

5.Scalability: Easily integrates with automatic packing, labeling, and sealing lines, providing a scalable packaging solution.

Conclusion

A robotic carton erector is an intelligent investment for businesses seeking to automate their secondary packaging process. With its precision mechanics, fast performance, and flexible adaptability, it enhances operational efficiency and packaging consistency.

Whether you're scaling up production or aiming for smart factory automation, this solution ensures a smooth and efficient start to your packaging line—making it essential for manufacturers in a competitive market.

Get the latest price? We'll respond as soon as possible(within 12 hours)