Heat Shrink Wrap Machine: An Efficient and Versatile Packaging Solution

Shrink Wrap Machine: An Efficient and Versatile Packaging Solution

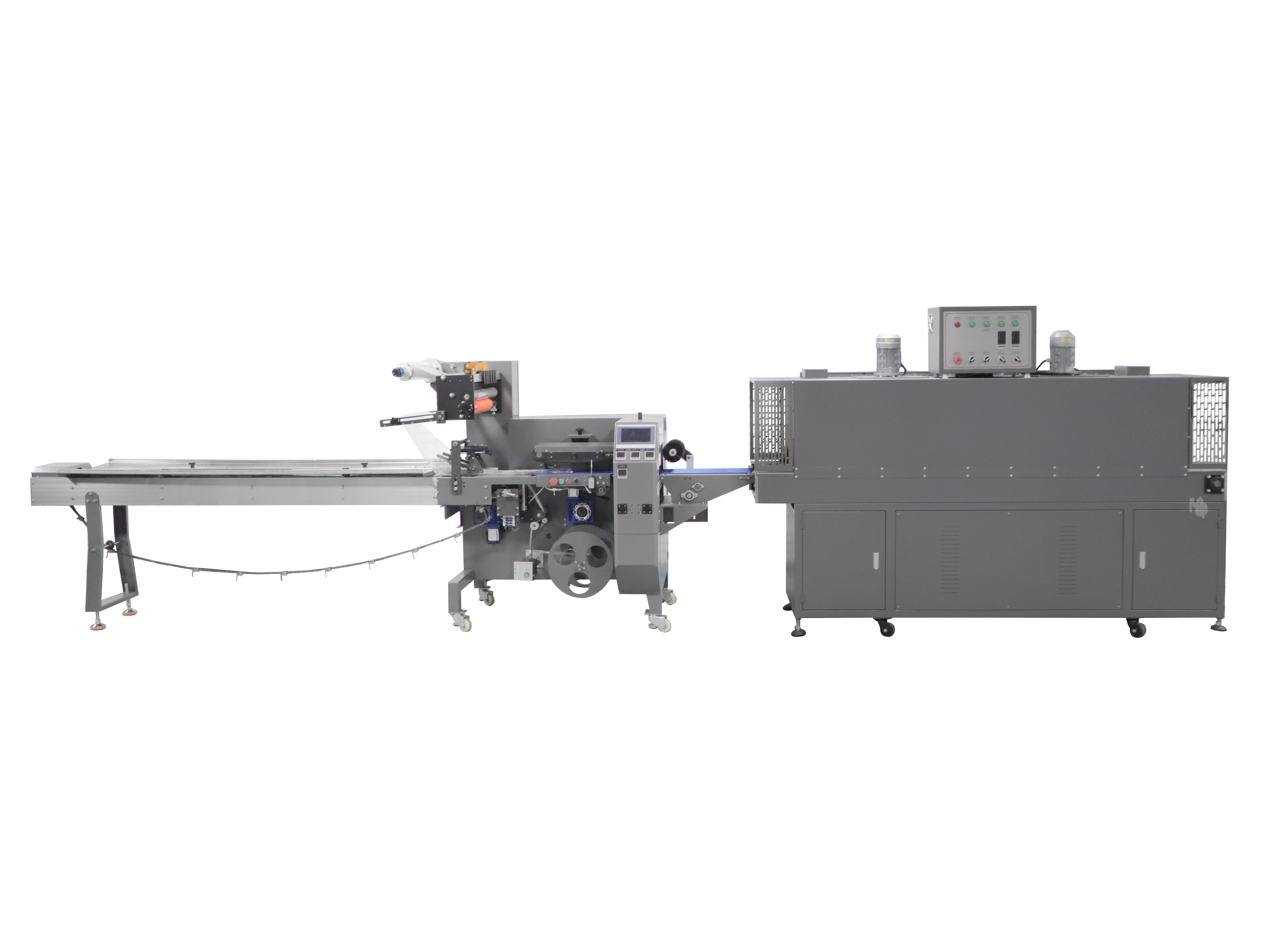

In modern industrial production, heat shrink wrap machines have become indispensable due to their efficiency, flexibility, and multifunctionality. Widely used across industries such as food, beverages, electronics, and cosmetics, this equipment provides protective, sealed, and aesthetically pleasing packaging through the use of shrink film. It’s an ideal solution for various packaging needs.

What is a Heat Shrink Wrap Machine?

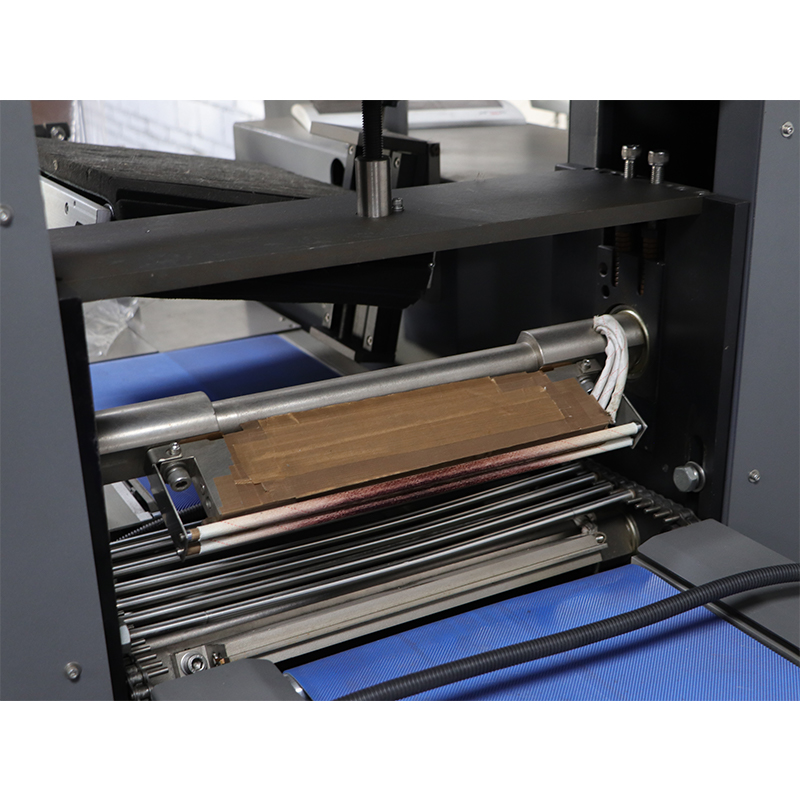

A heat shrink wrap machine is a device that uses shrink film to enclose products. When exposed to heat (via hot air or infrared), the film shrinks tightly around the product, creating a protective layer. This packaging method effectively safeguards items from dust, moisture, and damage during transportation and storage.

What is a Heat Shrink Wrap Machine?

A heat shrink wrap machine is a device that uses shrink film to enclose products. When exposed to heat (via hot air or infrared), the film shrinks tightly around the product, creating a protective layer. This packaging method effectively safeguards items from dust, moisture, and damage during transportation and storage.

Key Features of a Heat Shrink Wrap Machine

1. High Production Efficiency

Heat Shrink wrap machines streamline the entire process, from film cutting and sealing to shrinking and forming. They are ideal for large-scale production, significantly boosting productivity.

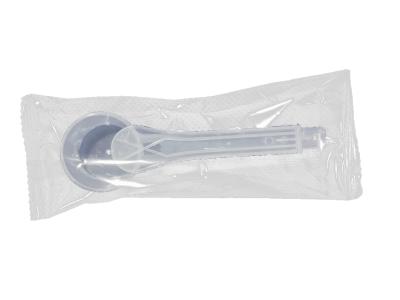

2. Exceptional Protection

The shrink film provides protection against dust, moisture, and scratches. Its tear-resistant properties ensure the integrity of the packaging.

3. Broad Applicability

Whether for single-item packaging or bundling multiple items together, shrink wrap machines are highly versatile. They are commonly used for packaging food (e.g., bottled water, canned goods), electronics (e.g., batteries, accessories), and various consumer goods.

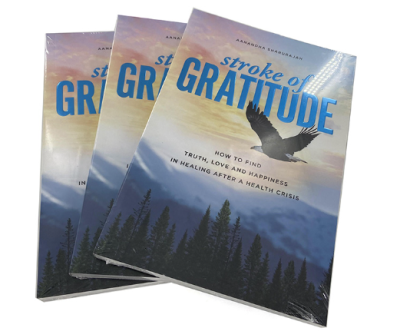

4. Enhanced Visual Appeal

The tightly wrapped film conforms to the product's shape, offering a sleek, professional appearance. Transparent films are particularly advantageous for showcasing products.

5. Flexibility and Adjustability

Heat Shrink wrap machines can be tailored to accommodate products of various shapes and sizes. They are compatible with different shrink film materials, such as PVC, PE, and POF, for diverse packaging needs.

Advantages and Value of Shrink Wrap Machines

1. Cost Efficiency

Shrink films are lightweight and require less material compared to other packaging methods, reducing overall costs.

2. Increased Product Value

Attractive shrink-wrapped packaging enhances the product's visual appeal and strengthens brand competitiveness.

3. Ease of Use

Equipped with user-friendly control panels, shrink wrap machines are easy to operate and maintain, requiring minimal training.

4. Environmental Compatibility

Many shrink film materials are recyclable, aligning with the growing demand for sustainable packaging solutions.

Conclusion

Heat Shrink wrap machines are a versatile and cost-effective packaging solution, combining efficiency, adaptability, and sustainability. By ensuring high production efficiency and premium packaging quality, they empower businesses to optimize packaging costs and enhance product competitiveness. If you’re looking for top-notch shrink wrap machines, explore our solutions tailored to meet your specific needs.

Get the latest price? We'll respond as soon as possible(within 12 hours)