Revolutionizing Snack Packaging: Advanced Vertical Potato Chip Packaging Solutions

Revolutionizing Snack Packaging: Advanced Vertical Potato Chip Packaging Solutions

In the competitive world of snack manufacturing, potato chips remain one of the most popular products globally, requiring efficient and reliable packaging solutions to meet ever-growing consumer demand.

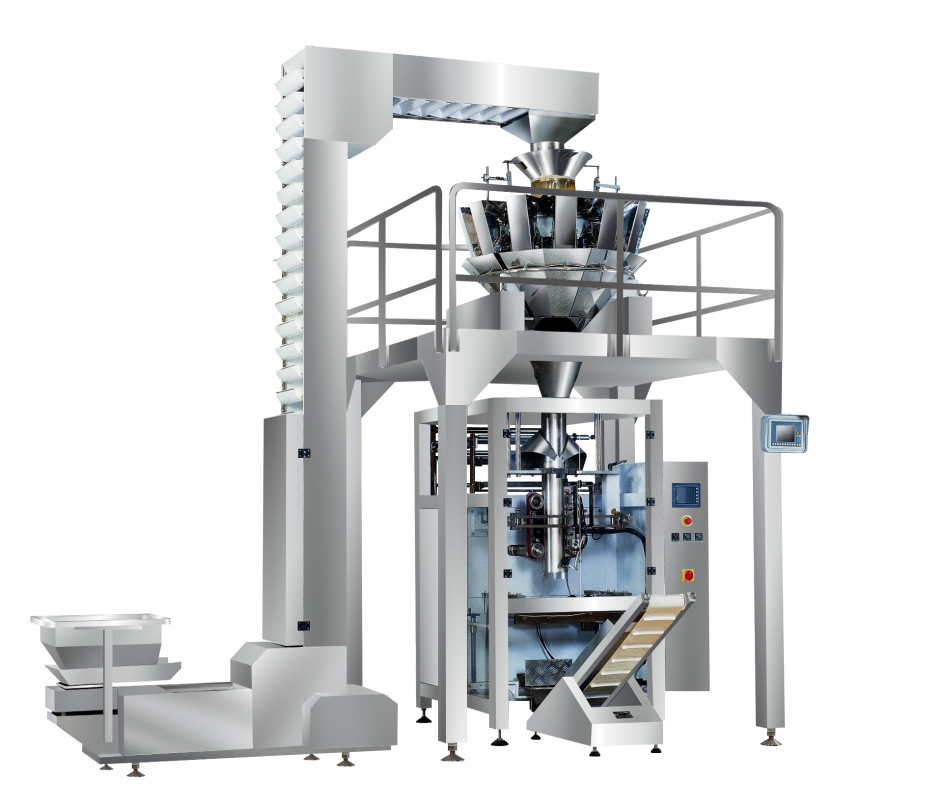

The vertical potato chip packaging machine is specifically designed to address the unique challenges of packaging delicate and lightweight products like chips. With speeds of up to 60 bags per minute, it ensures that manufacturers can maintain high productivity without compromising product quality.

Key components:

1. Z-type Elevator: Used for feeding materials into the multi-head weigher.

2. 10-Head Weigher: Designed for weighing granular products.

3. Integrated Weigher: The weigher is mounted directly on the main packaging machine, eliminating the need for a separate supporting platform. This helps save on both cost and space, making it especially ideal for facilities with limited budgets or space constraints.

4. Optional Components: The system also offers optional items such as a finished product conveyor and a metal detector.

Applications:

Although this machine is ideally suited for plantain chips, it is versatile enough to handle various other small granular products such as potato chips, coated peanuts, cashews, popcorn, frozen food and more.

Features and Benefits of the Potato Chips Packaging Machine:

1. Fully Automatic Operation: This machine automates the entire process from material feeding, weighing, and filling the product into bags, to bag making, sealing, and printing the production date, lot number, and batch number.

2. User-Friendly Control: Equipped with a PLC and a touch screen interface, the system is smart, intuitive, and simple to operate.

3. Precise Temperature Control: The machine features a PID temperature controller that independently manages the vertical and horizontal sealing temperatures with high accuracy.

4. Real-Time Monitoring: The system continuously displays the operational status. If an issue arises, the safety device triggers an alarm and the machine stops automatically for safety.

5. High-Quality Materials: All parts that come into contact with the product are made of stainless steel 304 or other food-grade materials to ensure hygiene and safety.

6. Adjustable Bag Settings: By changing the bag former, the machine easily adjusts bag width. The bag length can be set directly via the touch screen.

7. Compact Design: The machine’s space-saving design ensures a small footprint and facilitates easier commissioning, cleaning, and maintenance.

8. Long-Term Reliability: All key components come with a 24-month warranty, and the machine uses internationally recognized, high-quality components to ensure long-term stability.

9. Simplified Operation: All pneumatic and electrical components are housed in independent electrical boxes for easier operation.

10. Safety Features: Equipped with a safety door that will automatically stop the machine when opened, ensuring better protection for operators.

11. Optional Features:

- Metal Detector: Can be added to inspect finished packages and reject any that contain metal particles.

- Check Weigher: Can verify the weight of each bag, rejecting those that fall outside acceptable weight ranges.

- Date Printer: Options available for ribbon code printing or other types of printers depending on the specific printing needs.

This packaging machine offers a robust, versatile solution for packaging granular products, with a focus on automation, precision, and safety.

Get the latest price? We'll respond as soon as possible(within 12 hours)