Horizontal Heat Shrink Wrapping Machine for Milk Powder Scoops: Secure, Efficient, and Hygienic Packaging

Horizontal Heat Shrink Wrapping Machine for Milk Powder Scoops: Secure, Efficient, and Hygienic Packaging

Introduction

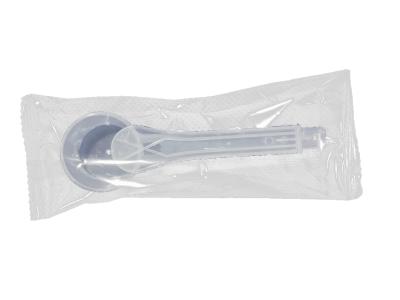

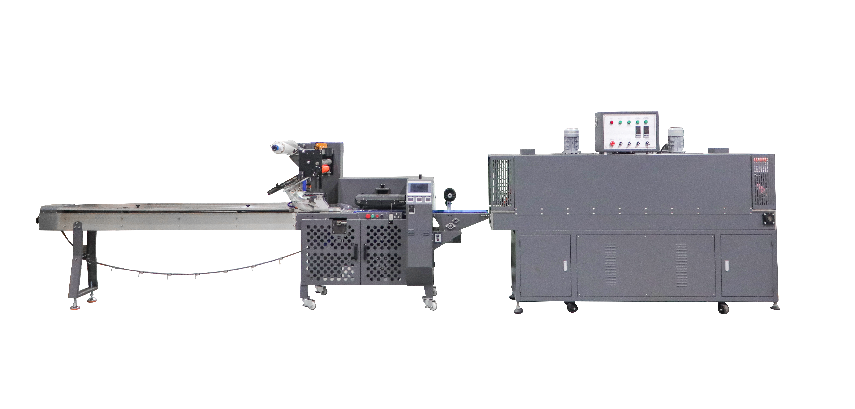

Milk powder scoops are essential accessories in infant formula and nutritional powder packaging. To maintain hygiene and ensure safe distribution, these scoops require high-quality, tamper-proof packaging. A horizontal heat shrink wrapping machine offers an efficient, automated solution, wrapping milk powder scoops securely in shrink film to provide protection against contamination and damage. This article explores the key features, working process, and advantages of using a heat shrink wrapping machine for milk powder scoops.

Key Features

1. High-Speed Operation

Capable of packaging up to 150 scoops per minute, ensuring high production efficiency.

Continuous operation with minimal downtime optimizes production output.

2. Automated Packaging Process

Integrates feeding, wrapping, sealing, shrinking, and cutting into one seamless process.

Reduces manual handling, improving hygiene and packaging consistency.

3. Precision Sealing and Shrink Wrapping

Advanced heat control ensures uniform shrinkage, maintaining a tight and protective seal.

Prevents product exposure to dust, moisture, and external contaminants.

4. User-Friendly Interface

Intuitive touchscreen control for easy operation and real-time parameter adjustments.

Supports multiple packaging formats to meet diverse production needs.

5. Compact and Durable Design

Space-saving structure with durable stainless-steel construction for long-term reliability.

Suitable for high-volume production in food and pharmaceutical industries.

Working Principle

The horizontal heat shrink wrapping machine follows a streamlined and efficient packaging process:

1. Scoop Feeding

The scoops are automatically fed into the machine using a conveyor system, ensuring precise alignment.

2. Film Wrapping

The scoops are wrapped with shrink film, forming a protective layer around the product.

3. Sealing and Cutting

The packaging film is sealed tightly and cut into individual packs, maintaining a professional and secure finish.

4. Heat Shrinking

The packaged scoops pass through a heat tunnel where the film shrinks tightly around the product, creating a secure and tamper-evident package.

5. Finished Product Discharge

The final packaged scoops are conveyed for further processing, storage, or distribution.

Applications

Horizontal heat shrink wrapping machines are ideal for:

Milk Powder Scoops:Ensuring hygienic and tamper-proof packaging.

Pharmaceutical Accessories:Providing secure packaging for medical measuring spoons.

Small Plastic Parts :Used in the food and consumer goods industries.

Advantages of Horizontal Heat Shrink Wrapping Machines

Improved Product Hygiene:Fully enclosed packaging prevents contamination.

Increased Efficiency:High-speed operation reduces labor costs and boosts output.

Enhanced Protection:Shrink film safeguards products from external elements.

Flexible Packaging Options:Adjustable settings accommodate different product sizes.

Cost-Effective Solution:Reduces material waste and improves operational efficiency.

Conclusion

A horizontal heat shrink wrapping machine is an essential solution for food and pharmaceutical manufacturers looking to enhance packaging efficiency, product protection, and hygiene. With its automated, high-speed operation and precise sealing technology, it ensures secure, visually appealing, and contamination-free packaging for milk powder scoops and other small plastic accessories. Investing in this advanced packaging solution helps businesses streamline production, reduce costs, and meet high-quality packaging standards.

Get the latest price? We'll respond as soon as possible(within 12 hours)