Key Factors in Pet Food Packaging and Choosing the Right Packaging Machine

Key Factors in Pet Food Packaging and Choosing the Right Packaging Machine

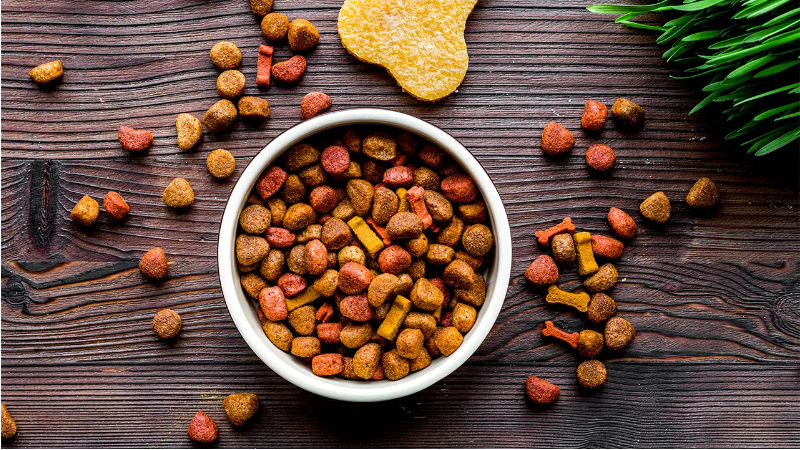

The pet food industry is growing rapidly, with increasing consumer demand for high-quality, safe, and convenient packaging. A well-designed package not only ensures product freshness but also enhances brand competitiveness. Selecting the right packaging machine is crucial for pet food manufacturers. This article explores key factors in pet food packaging and recommends suitable packaging machines for different product types.

Key Factors in Pet Food Packaging

1. Sealing Performance

Pet food, such as dry kibble, wet food, and freeze-dried products, requires excellent sealing to prevent moisture, spoilage, or contamination. Wet food and meat-based products, in particular, need reliable heat sealing or vacuum packaging to maintain long-term freshness.

2. Compatibility with Packaging Materials

Different pet foods require different packaging materials:

Dry food: Plastic bags (PE, PET+aluminum foil) or paper bags with moisture and oxygen barriers.

Wet food & fresh food: Aluminum foil pouches or resealable plastic bags for leak-proof and freshness preservation.

Snacks & freeze-dried food:Resealable zipper bags,canned packaging,or individual sachets.

3. Flexibility in Packaging Sizes

Packaging sizes vary from small sachets (50g, 100g) to large bulk packaging (5kg, 10kg). Manufacturers need flexible machines that can adjust to different packaging requirements.

4. Automation Level

Large-scale production requires highly automated packaging machines to reduce manual labor and increase efficiency. Machines with automatic weighing, filling, and sealing functions improve overall production speed and consistency.

5. Traceability

Modern packaging machines offer coding and labeling functions to print production dates, batch numbers, and barcodes for compliance with food safety regulations.

Suitable Packaging Machines for Pet Food

1. Vertical Packaging Machine

Suitable for granular and powder pet food (e.g., kibble, freeze-dried food).

Automates weighing, filling, bag forming, sealing, and cutting.

Compatible with plastic film and aluminum foil.

Suitable for medium to large packaging (100g-5kg).

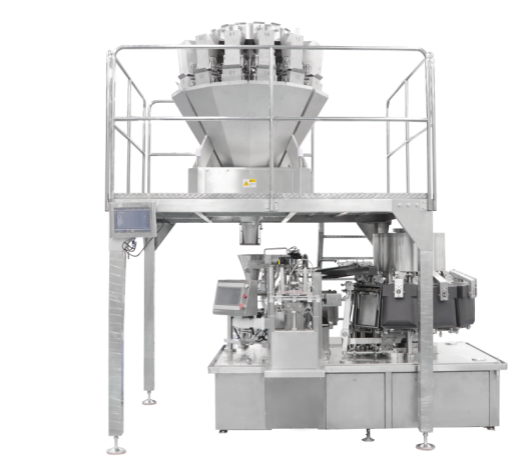

2. Premade Pouch Packaging Machine

Suitable for high-end pet food (e.g., wet food, snacks, zipper bags).

Works with preformed pouches (zipper bags, stand-up pouches).

Handles powders, liquids, and solid food.

Provides high-quality, visually appealing packaging.

3. Vacuum Packaging Machine

Suitable for pet food requiring long-term storage (e.g., freeze-dried food, wet food).

Removes air to maintain product freshness.

Ideal for premium products.

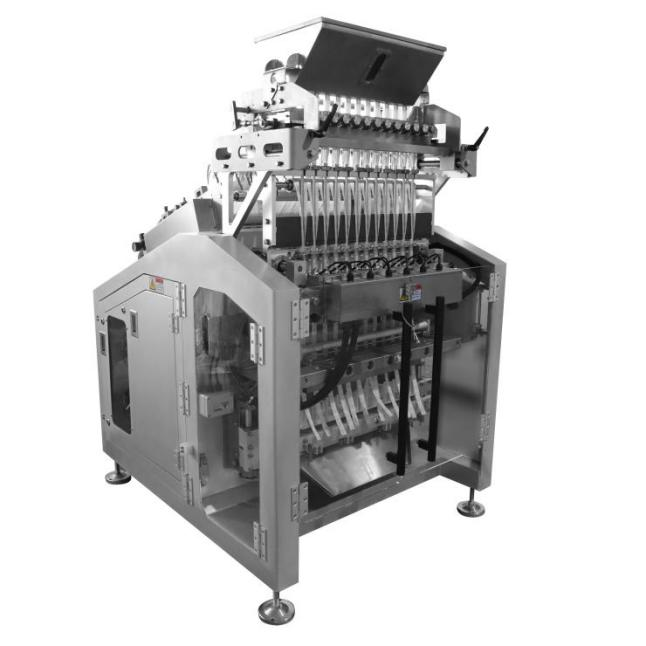

4. Multi-Lane Packaging Machine

Suitable for single-portion pet food sachets.

Handles small packaging (10g-100g).

Designed for high-speed, high-volume production.

Conclusion

Pet food packaging affects both product shelf life and brand competitiveness. Manufacturers should select the right packaging machine based on their product type, with vertical packaging machines for dry food, pre-made pouch machines for wet food and snacks, and vacuum machines for long-term storage. As quality expectations rise, automated, efficient, and eco-friendly packaging solutions will shape the future of the pet food industry.

Get the latest price? We'll respond as soon as possible(within 12 hours)