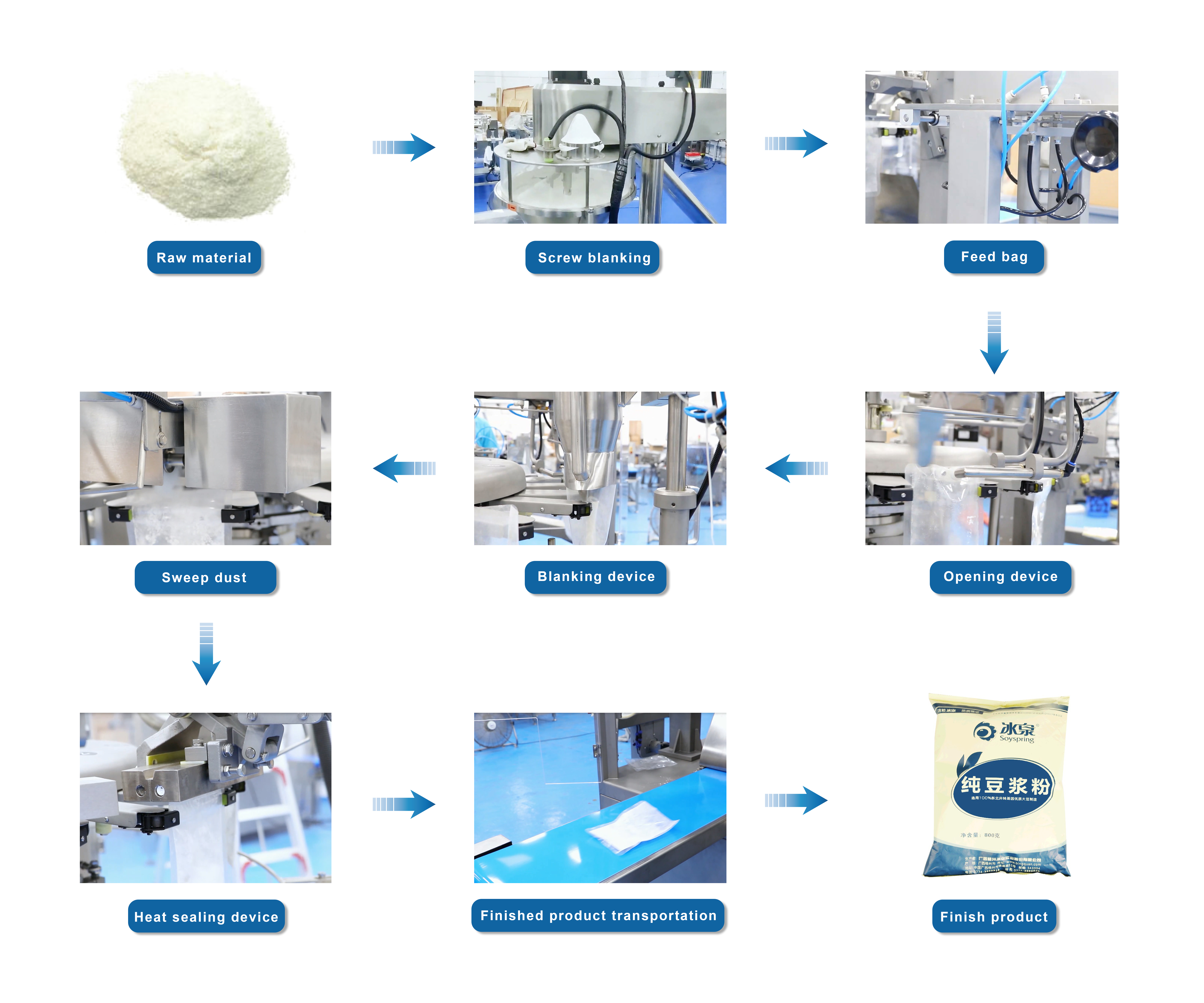

Instructions of Powder premade pouch packaing machine

Powder premade pouch packaing machines are usually composed of multiple components, such as closed screw elevators, screw measuring machines, multi station rotary feeding bag packaging machines, and finished product conveyors. These components work together to achieve the following functions:

Storage and loading: The storage tank is used to store powder raw materials, while the screw elevator is responsible for lifting the powder raw materials to the measuring system.

Measurement and filling:

The spiral measuring machine achieves precise powder measurement by precisely controlling the speed and time of the spiral. The measured powder is filled into pre made bags that have already been placed at the bag feeding station.

Bag feeding and sealing:

The bag feeding system is responsible for transporting prefabricated bags to the filling station and performing sealing operations after filling is completed. Sealing is usually done by heat sealing to ensure the sealing of the bag opening.

Printing and counting:

While sealing, the packaging machine can also perform operations such as date printing and batch number printing. At the same time, the counter will record the number of bags that have been packaged, facilitating production management.

Transportation and organization:

The finished product conveyor is responsible for transporting packaged products to designated locations and organizing them for subsequent transportation and storage.

Get the latest price? We'll respond as soon as possible(within 12 hours)