Horizontal Card Packaging Machine: Streamlining Card Product Packaging

Horizontal Card Packaging Machine: Streamlining Card Product Packaging

In the rapidly growing gaming industry, the packaging of game cards, such as collectible trading cards and board game pieces, has become a critical factor in ensuring both product protection and presentation quality. Horizontal card packaging machines are specifically designed to meet the needs of game card manufacturers, providing a fast, efficient, and precise solution for packaging a wide variety of card products. This article will delve into the features, working principles, and benefits of horizontal card packaging machines, particularly for the game card market.

Key Features

1. High-Speed Operation

The horizontal design allows for continuous, rapid packaging cycles, ensuring that production demands are met even during peak periods.

2. Automated Packaging Process

Integrated systems for feeding, wrapping, sealing, and cutting reduce labor costs and eliminate human error, ensuring each package meets strict quality standards.

3. Adjustable Configurations

With customizable settings for package size, sealing temperature, and speed, these machines can be adapted to accommodate various card dimensions and packaging materials.

4. Precision Sealing and Cutting

Advanced sensors and control systems ensure that each card package is sealed uniformly and cut precisely, protecting the cards from damage and contamination.

5. User-Friendly Interface

Modern control panels and intuitive software allow operators to monitor the packaging process in real time, adjust parameters quickly, and perform maintenance with ease.

6. Compact and Durable Design

The robust construction of horizontal packaging machines not only saves floor space but also guarantees long-term reliability even in high-volume production environments.

Working Principle

The horizontal card packaging machine operates on a simple yet effective process:

1. Material Feeding

The machine begins by feeding a roll of flexible packaging film horizontally. The film is pre-loaded onto a spool and unwound steadily to ensure a continuous supply.

2. Card Loading

Card products are fed into the machine using automated guides or conveyor belts that align the cards accurately. This ensures that each card is positioned perfectly for packaging.

3. Packaging Formation

As the cards reach the packaging station, the machine forms the film around them, creating a protective envelope. The horizontal layout allows the machine to package items gently, minimizing any risk of damage to delicate card surfaces.

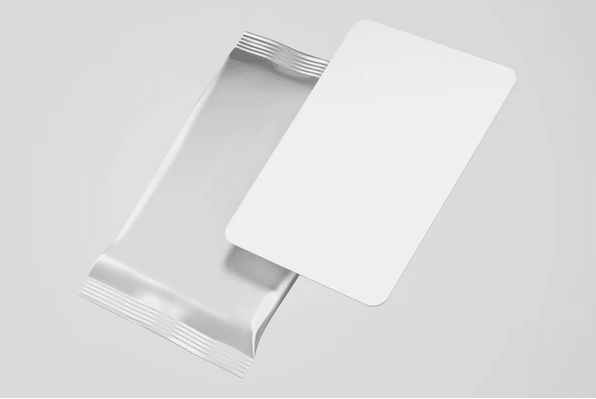

4. Sealing and Cutting

Once the cards are enveloped, high-precision heat sealing or pressure sealing mechanisms close the package securely. Immediately after sealing, the film is cut to produce individual packages ready for further processing or distribution.

Applications

Horizontal card packaging machines are versatile and can be used in various industries, including:

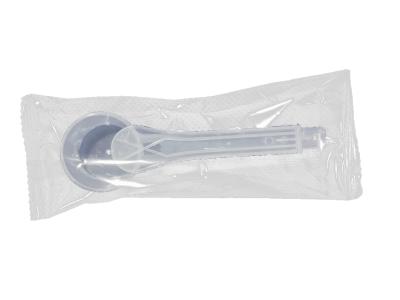

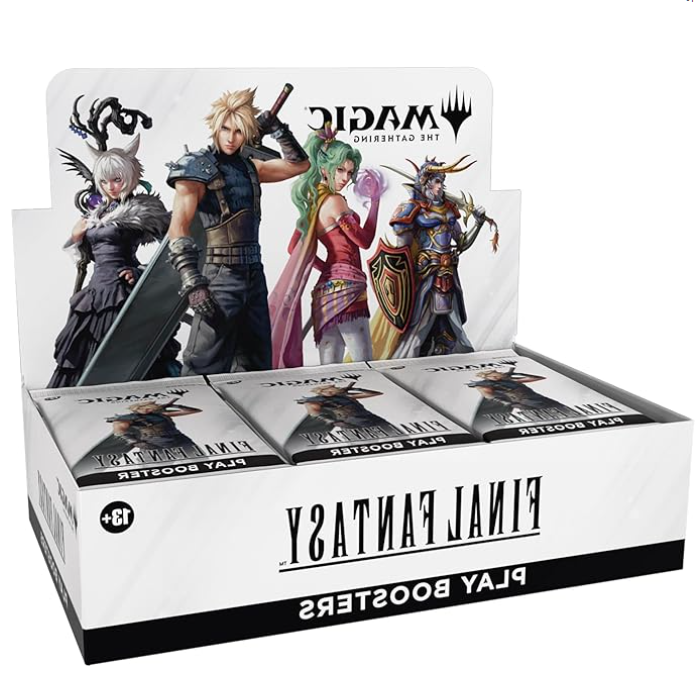

- Playing and Trading Cards

Protecting and presenting decks of playing or collectible trading cards in a professional, attractive manner.

- Greeting and Postcards

Offering an efficient solution for packaging greeting cards, postcards, and other stationery products with precision and care.

- Promotional and Gift Cards

Ensuring that promotional materials and gift cards are securely packaged and ready for immediate sale or distribution.

Advantages of Horizontal Packaging for Card Products

- Enhanced Productivity

The horizontal orientation is optimized for high-speed, continuous packaging, which significantly increases production throughput.

- Reduced Damage Risk

Gentle handling during the packaging process minimizes the risk of bending, scratching, or otherwise damaging sensitive card surfaces.

- Consistent Packaging Quality

Automation ensures uniformity in each package, which is essential for maintaining brand integrity and customer satisfaction.

- Cost Efficiency

With reduced manual labor, lower material wastage, and streamlined operations, manufacturers can achieve significant cost savings over time.

- Flexibility and Scalability

The adjustable features of the machine allow manufacturers to switch between different card sizes and packaging styles, catering to diverse market demands.

Conclusion

The horizontal card packaging machine stands out as an indispensable tool for manufacturers looking to enhance the efficiency and quality of their packaging processes. Its ability to package a wide range of card products quickly and accurately makes it ideal for high-demand markets such as gaming, business, and promotional products. By investing in a horizontal card packaging machine, companies can ensure that every package not only protects the product but also reflects the quality and professionalism of the brand.

Get the latest price? We'll respond as soon as possible(within 12 hours)