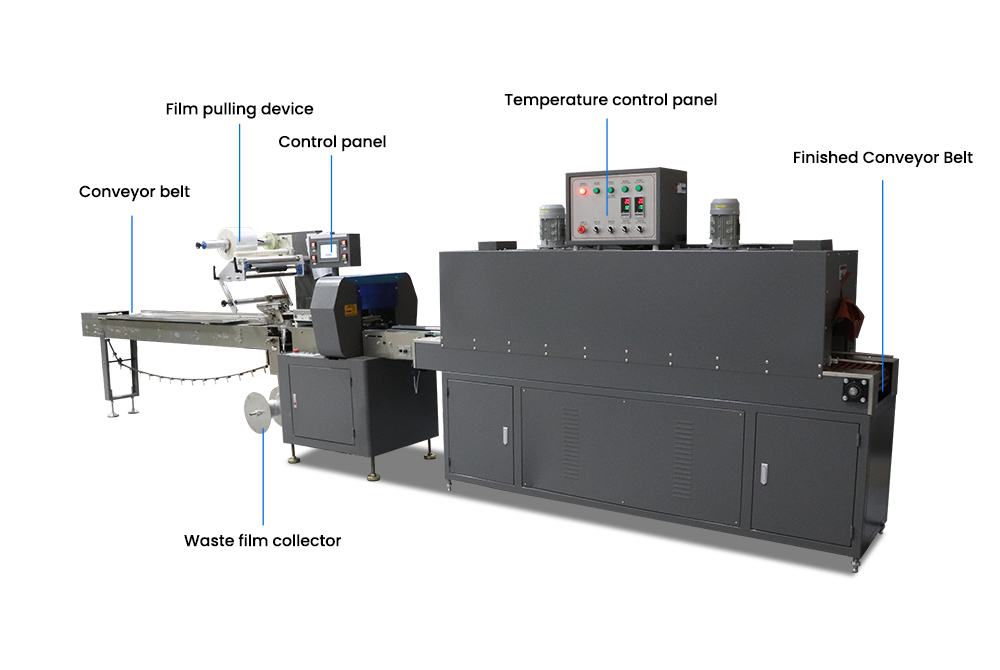

Heat shrink packaging machine operation precautions

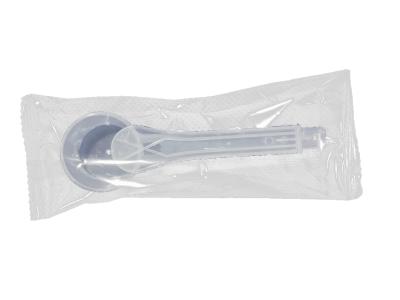

Heat shrink packaging machines occupy a certain market position at home and abroad, and are used more and more widely, such as groceries, electrical appliances, food, beverages, condiments, electronic parts, medicines and their packaging boxes, one or two box packaging, etc. However, during the design, production and trial production process, it was found that the following factors will also affect the effect of finished product packaging:

① Performance of film cutting knife and film sealing knife Before packaging, first level the film cutting knife and film sealing knife. The upper knife bed and lower knife bed must be adjusted to be parallel to each other; the pressure adjustment of the pressure knife spring must be basically the same. The individual knives must be coordinated while working. Otherwise, the plastic film will be cut off or the seal will be torn off, resulting in batches of waste products. Experimental results show that the working sequence of the film is optimal and greatly improves the shrinkage rate of the packaging.

② When designing various forms of heat shrink packaging machines, taking into account the performance of the hot air fan and the impact of the air flow system structure, the hot air fan must be selected first. At the same time, attention should be paid to the reasonable configuration of the hot air circulation duct system structure. If the fan performance is not good and the design of the inlet and outlet of the flexible plate, baffle, diverter, regulating plate and air flow system is unreasonable, a large amount of waste will be produced during heat shrink packaging, making debugging difficult. When the fan is working, the temperature can be evenly stirred up and down to achieve the best effect.

③ The impact of shrink film exhaust on items that require complete sealing and packaging should be paid special attention to. When the packaging machine transfers the packaged items to the heat shrink chamber, the packaging film begins to shrink under the influence of temperature, and the exhaust is usually eliminated through a small hole punch on the punch. When packaging large items, the number of punching holes should be increased, and there should be enough ventilation holes during the film feeding process, so that the shrinkage effect will be improved.

Get the latest price? We'll respond as soon as possible(within 12 hours)