Differences Between Horizontal Top Film Packaging Machine and Bottom Film Packaging Machine

Differences Between Horizontal Top Film Packaging Machine and Bottom Film Packaging Machine

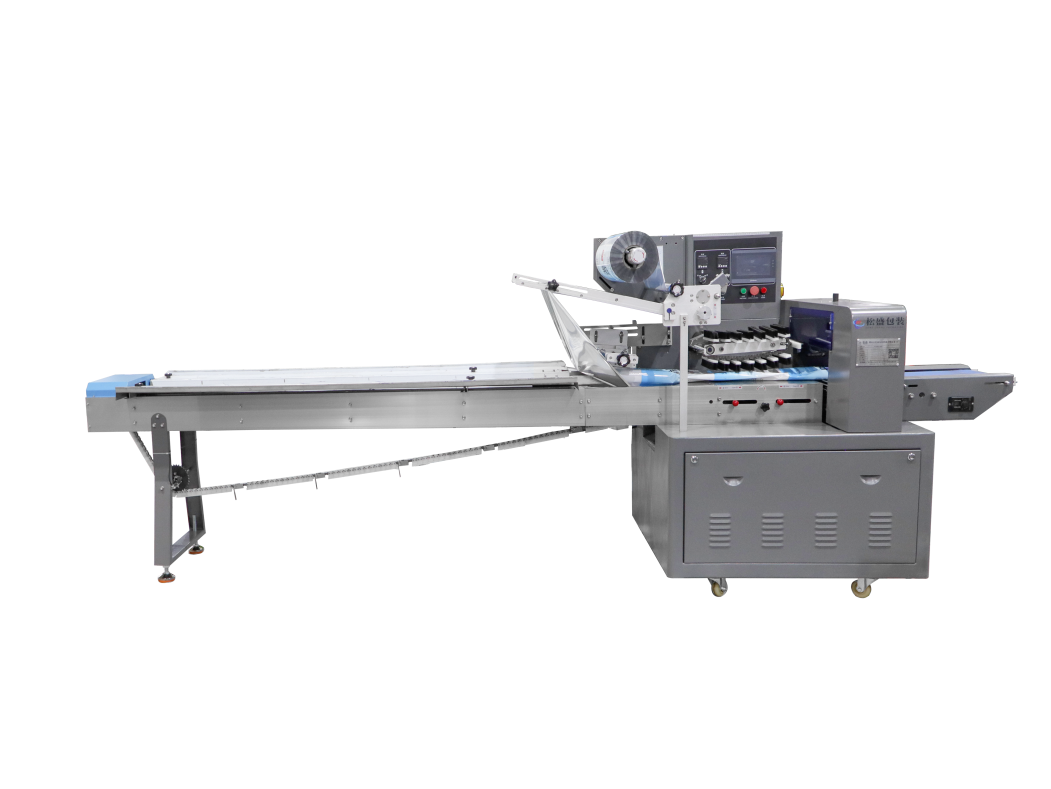

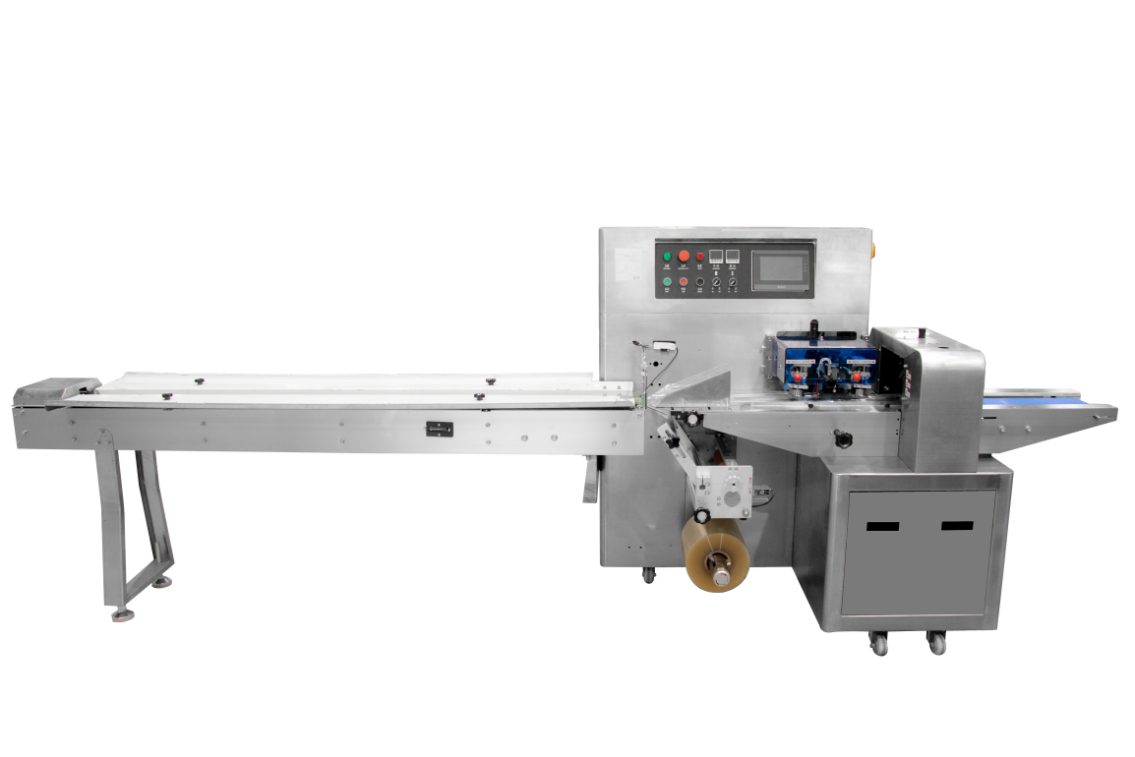

In modern packaging machinery, horizontal packaging machines are highly regarded for their efficiency and reliability. However, when deciding on a specific model, users often face a key question: should they choose a top film packaging machine or a bottom film packaging machine? While both are common types of horizontal packaging machines, they differ significantly in working principles, application scenarios, and design features. Below is a detailed analysis of their differences to help you make an informed decision.

1.Working Principles

Top Film Packaging Machine:

The film roll is installed at the top of the machine. The film covers the product from above and is sealed to complete the packaging process. This design is ideal for packaging styles where the film is required to tightly cover the top of the product.

Bottom Film Packaging Machine:

The film roll is located at the bottom of the machine. The film supports the product from underneath, and the packaging is completed with sealing and forming. This configuration is suitable for applications where the bottom of the product needs stability or structural integrity.

Top Film Packaging Machine:

Best for lightweight, smooth-surfaced, or regularly shaped products. Examples include cookies, cakes, chocolates, and small electronic components. It emphasizes the aesthetic appeal of the packaging, particularly the tightness and neatness of the top film.

Bottom Film Packaging Machine:

Ideal for heavier, irregularly shaped, or deformable products, such as frozen foods, tray-based items, and bulky products. The bottom film design provides stable support during the entire packaging process.

3. Structural and Design Features

Top Film Packaging Machine:

1. Simple structure, easy to operate and maintain.

2. Smaller footprint, making it suitable for factories with limited space.

3. Faster packaging speeds, meeting the needs of high-volume production.

Bottom Film Packaging Machine:

1. More complex structure to ensure stability and uniform film forming.

2.Designed for products requiring strong bottom support, providing comprehensive protection.

3. Suitable for heavy-duty applications, such as logistics and cold chain industries.

4. Packaging Results

Top Film Packaging Machine:

Focuses on the tightness and aesthetic appeal of the packaging, particularly the visual presentation of transparent films.

Bottom Film Packaging Machine:

Offers robust and stable packaging, emphasizing support from the base and overall durability. Ideal for products requiring stability during transportation and storage.

5.Final Recommendations

For lightweight, regularly shaped products with smooth surfaces, such as snacks or lightweight industrial products, where speed and efficiency are prioritized, a top film packaging machine is the best option.

For irregularly shaped, heavier products that require strong bottom support, such as frozen foods or bulky goods, the bottom film packaging machine is more suitable.

----

Regardless of your choice, selecting the right packaging machine depends on the characteristics of your product, production requirements, and budget. If you’re unsure, feel free to contact us. Our team of experts is ready to provide tailored solutions that align with your specific needs.

Get the latest price? We'll respond as soon as possible(within 12 hours)