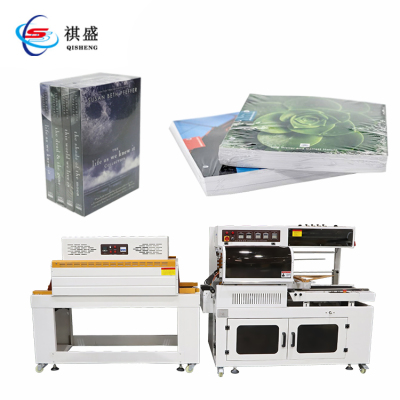

Tissue towel Heat Shrink Wrapping Packaging Machine

The Tissue towel Heat Shrink Wrapping Packaging Machine is an advanced equipment specially designed for the automation of tissue product packaging. It combines heat shrink technology and sealing and cutting technology to efficiently and accurately complete the packaging process of tissue paper.

Details

Tissue towel Heat Shrink Wrapping Packaging Machine

| Volume of machine packaging | 3-7.7m³ | Max package size | Length Unlimited&height ≤250mm | |

| Film material | PVC,POF,PP | Air supply | 6.0-8.0kgf/c m³ | |

| Speed | Max 230bags/min | Machine weight | 300KG | |

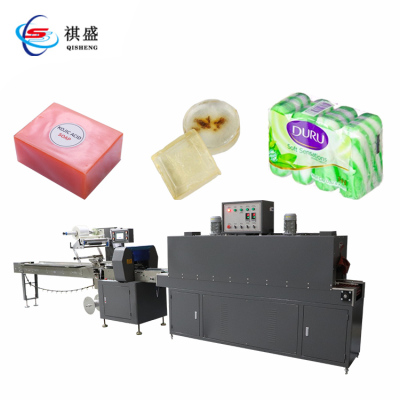

| Power | 220V 50/60Hz 1.35KW | Packing items | Fruit,fresh meat, item with tray etc | |

| Machine size | 3770*720*1420mm(L*W*H) | Maximum package size W h width | 300mm~800mm | |

Description:

1. Heat shrink furnace: located at the rear or side of the packaging machine, it is a heated tunnel or chamber. After initial packaging (such as bagging or labeling), tissues will be sent into a heat shrink furnace. The hot air or infrared heating source inside the furnace will soften and uniformly shrink the packaging film, tightly adhere to the tissue, and form a flat and beautiful packaging appearance.

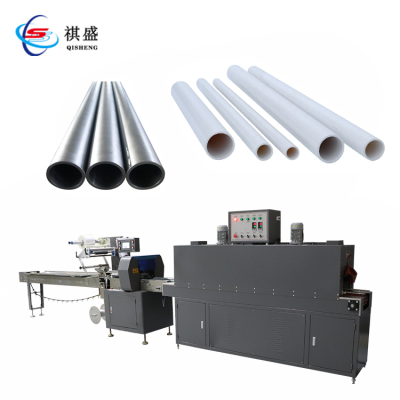

2. Conveyor system: composed of conveyor belts, rollers, or other forms of conveying machinery, responsible for transporting tissues from one end to the other, passing through different packaging stations, and finally entering the heat shrink furnace. This system requires precise control of speed and stability to ensure that tissues do not shift or get damaged during the packaging process.

3. Sealing and cutting device: Before the tissue enters the heat shrink furnace, it usually needs to go through a sealing and cutting process. This device will first fold the packaging film around the tissue and seal both ends, and then use a high-temperature blade or heat seal to quickly cut off the excess packaging film, completing the initial packaging work. The quality and speed of sealing and cutting directly affect the subsequent heat shrinkage effect and the overall packaging quality.

4. Control system: It is the brain of the entire machine, responsible for coordinating the operation of various parts. Through touch screens, PLCs, or other advanced control systems, operators can easily set packaging parameters, monitor machine status, and handle fault alarms. The control system can also achieve linkage control of automated production lines, improving production efficiency and stability.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)