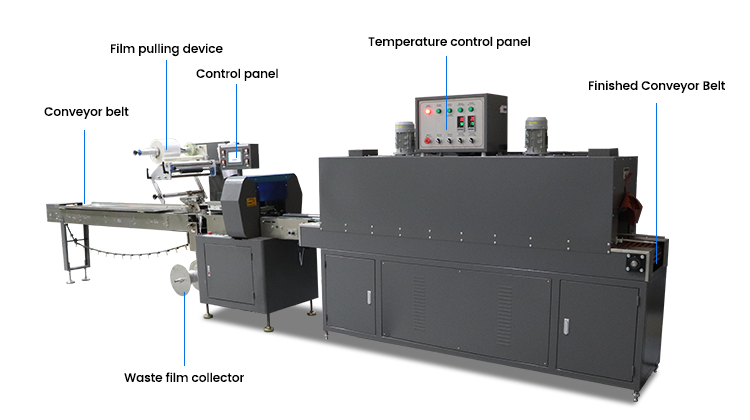

Soap heat shrink wrapping packaging machine

This Soap heat shrink packaging machine realizes a fully automated process from soap feeding, packaging to heat shrink, greatly improving production efficiency and reducing the need for manual operation.

Details

Soap heat shrink packaging machine

| Bag width | 30-110mm | Weight range | 30-1000g | |

| Conveying speed of stove | Max 10m/min | Functions | Filling,Labeling,Sealing | |

| Speed | Max 130bags/min | Machine weight | 500KG | |

| Machine Power | 220V 50Hz 2.7KW | Packing items | Bottle,box.soap etc | |

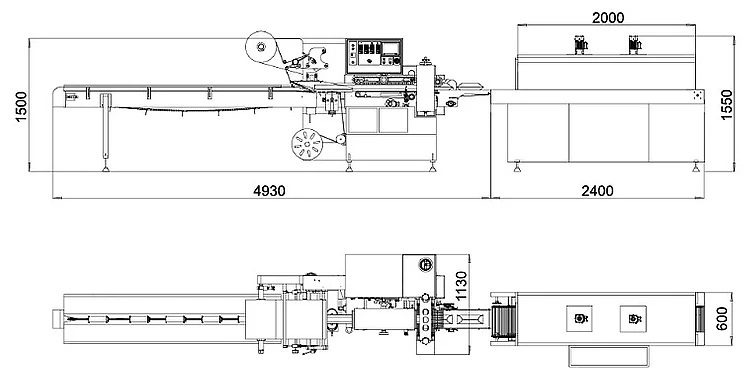

| Machine size | 4350*900*1480mm(L*W*H) | Film width | Max 420mm | |

| Tunnel stove Power | 15KW | Tunnel size | 2400*550*1700mm | |

Description:

1. Efficient automation: This Soap heat shrink packaging machine realizes a fully automated process from soap feeding, packaging to heat shrink, greatly improving production efficiency and reducing the need for manual operation.

2. Heat shrink technology: Through the built-in heating element, the machine can quickly shrink the plastic film placed on the soap, tightly adhering to the surface of the soap, forming a beautiful and highly protective packaging. This packaging method not only effectively protects soap from external pollution and damage, but also enhances the overall visual effect of the product and increases its attractiveness.

3. Precise positioning: During the packaging process, the machine ensures that each piece of soap is accurately placed in the packaging film through a precise mechanical structure and control system, and the packaging film can uniformly shrink on the surface of the soap, avoiding problems such as wrinkles or offset.

4. Safety and hygiene: As a production equipment for food or daily chemical products, this heat shrink packaging machine has been designed with full consideration of hygiene and safety factors. All parts in contact with soap are made of non-toxic and easy to clean materials to ensure the hygiene quality of the product.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)