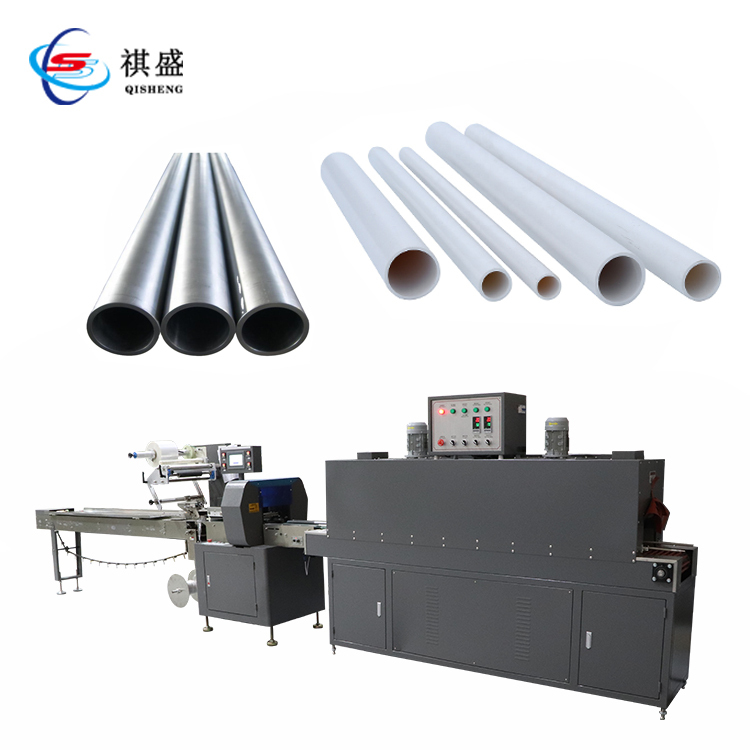

Aluminum tube heat shrink packaging machine

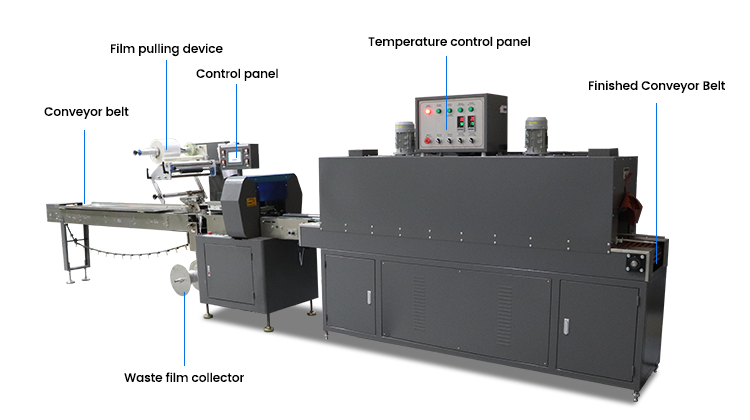

Aluminum tube heat shrink packaging machine is a mechanical equipment specifically used for aluminum tube packaging. Its working principle is to shrink the heat shrink film by heating and tightly wrap it on the surface of the aluminum material, thereby achieving the purpose of packaging

Details

Aluminum Tube Heat Shrink Packaging Machine

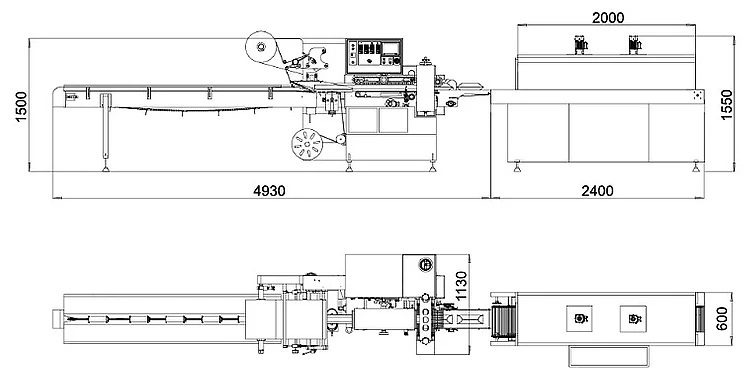

| Bag width | 30-110mm | Weight range | 30-1000g | |

| Conveying speed of stove | Max 10m/min | Functions | Filling,Labeling,Sealing | |

| Speed | Max 130bags/min | Machine weight | 500KG | |

| Machine Power | 220V 50Hz 2.7KW | Packing items | Carrot,banana.cucumber etc | |

| Machine size | 4350*900*1480mm(L*W*H) | Film width | Max 420mm | |

| Tunnel stove Power | 15KW | Tunnel size | 2400*550*1700mm | |

Description:

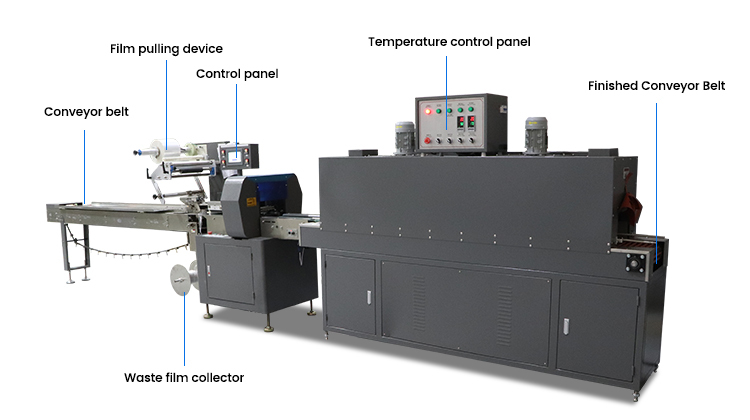

The working principle of the aluminum tube heat shrink packaging machine mainly includes three key steps: coating, heating shrinkage, and cooling shaping.

1.Coating: First, apply the heat shrink film onto the aluminum material to be packaged, ensuring that the film can fully cover the surface of the aluminum material.

2.Heat shrink: Subsequently, the aluminum tube enters the heating area of the heat shrink packaging machine. Here, the heat shrink film is heated by a heating device to shrink and tightly adhere to the surface of the aluminum material.

3.Cooling and shaping: Finally, the aluminum material that has been heated and shrunk enters the cooling area, and is quickly cooled and shaped through a cooling device, thus completing the entire packaging process.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)