Konw before buying a packaging equipment

2023-10-30 14:05

1.The cost of packaging equipment

Packaging machinery is customer-specific, so establishing "standard pricing" is often unrealistic. But we can offer a range: For a fully automated system, you can expect to pay mid-five figures, up to millions of dollars.

Pricing depends largely on your unique needs: the products you want to package, the speed you want to achieve, your bag style and size, the complexity of your process, and how quickly you need your machine to deliver.

Generally speaking, the more complex, customized, or high-speed the packaging process, the more you can expect to pay.

2.Packaging size and packaging methods

Before purchasing a packaging machine, knowing the details of the products and packaging you will be filling will make your job easier. When purchasing a vertical flow packaging machine (VFFS), a horizontal flow packaging machine (HFFS) or a Doyback bag packaging machine, please note that the packaging width is fixed on the machine and cannot be changed later. and packaging methods. If you plan to package your products in roll film packaging or pre-made bags.

3.Difference between semi-automatic and fully automatic packaging systems

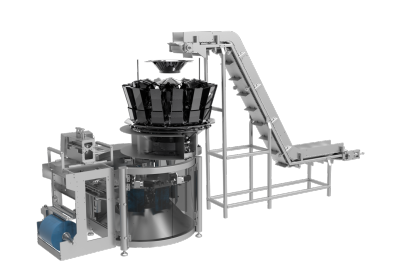

Fully automated packaging systems are optimized for high speeds and minimal human involvement. These solutions are best suited for companies that run a large number of products with relatively small changes. A fully automated production line can include equipment that feeds product into the system, scales that weigh the product, and machines that place the product into bags. Automated systems offer high levels of accuracy and consistency but require greater upfront investment.

Semi-automatic packaging systems still require a lot of labor. For example, a company may use automatic scales to weigh products but require humans to portion the products into bags and seal them. If you're not ready for full automation, a semi-automatic packaging line is a great place to start. In many cases, individual components of a semi-automated production line can later be integrated with other equipment to create a fully automated system. Overall, semi-automatic packaging lines have a much lower cost of entry, but are slower and less precise than fully automatic systems.

4.Can one packaging machine handle bags of different styles, sizes and products?

The short answer is "usually, yes." Adjusting the machine to accommodate different bags is called a changeover, which can take anywhere from a few minutes to a few hours, depending on many variables.

The longer answer is: Sometimes a one-size-fits-all machine isn't the best choice. The more diverse your needs are, the more it makes sense to invest in multiple systems or automate only certain parts of the process. The reason is that packaging machines are optimized to operate within certain parameters. If your needs vary, adapting to these changes in machine parameters can be complex, costly, and inefficient. Sometimes it's better to have a machine that does one thing well than a machine that does a lot of things "okay."

Purchasing a packaging machine is a long-term investment. A relationship that will last for many years begins with the packaging machine manufacturer. In this regard, choosing the right machine manufacturer is very important.

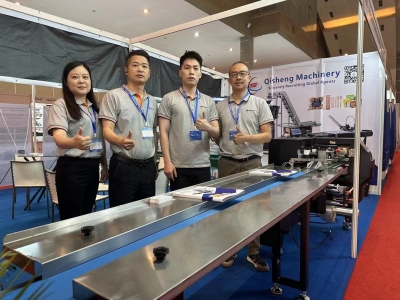

Choose Qisheng Machinery and enjoy lifelong equipment maintenance services!!!

Get the latest price? We'll respond as soon as possible(within 12 hours)