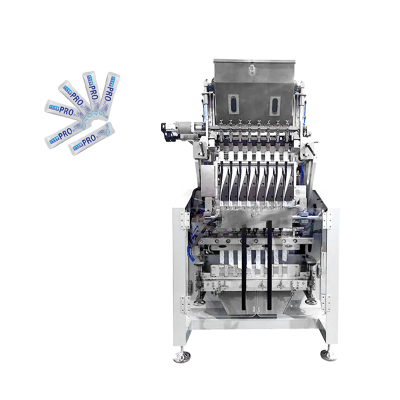

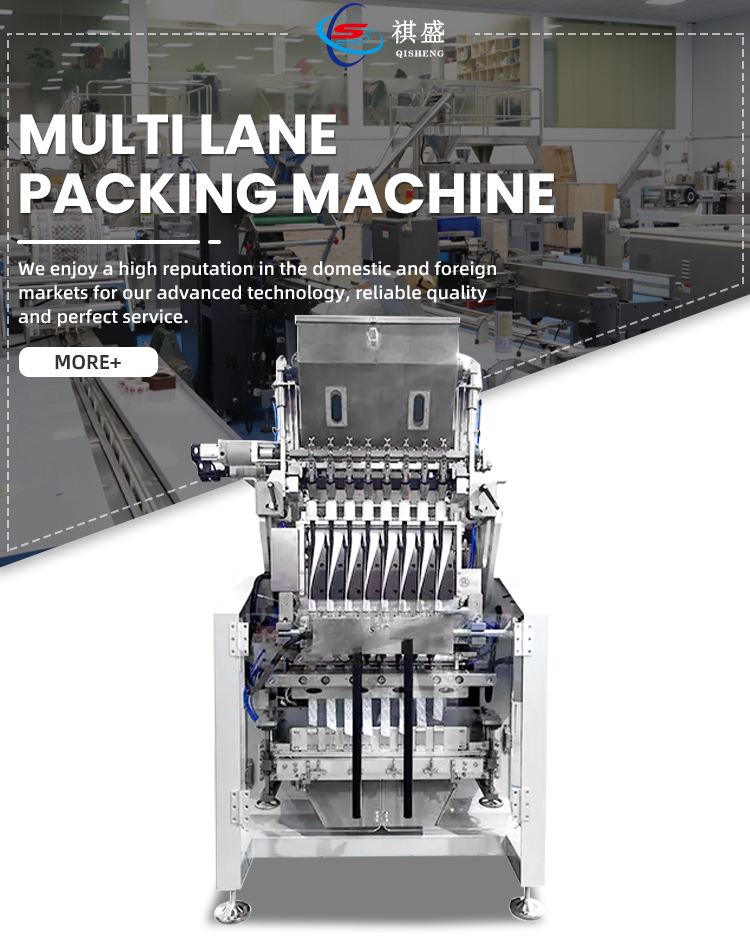

Sugar Multi Lane Packing Machine

Powder multi lane packaging machine, also known as powder multi lane packaging machine or multi lane powder packaging machine, is mainly used for fully automated packaging and sealing of powder products in small bags. This machine is suitable for automatic packaging of small bags of powder materials that are not easy to flow, such as milk powder, soy milk powder, starch, pharmaceutical powder, pesticide powder, coffee powder, seasoning powder, etc.

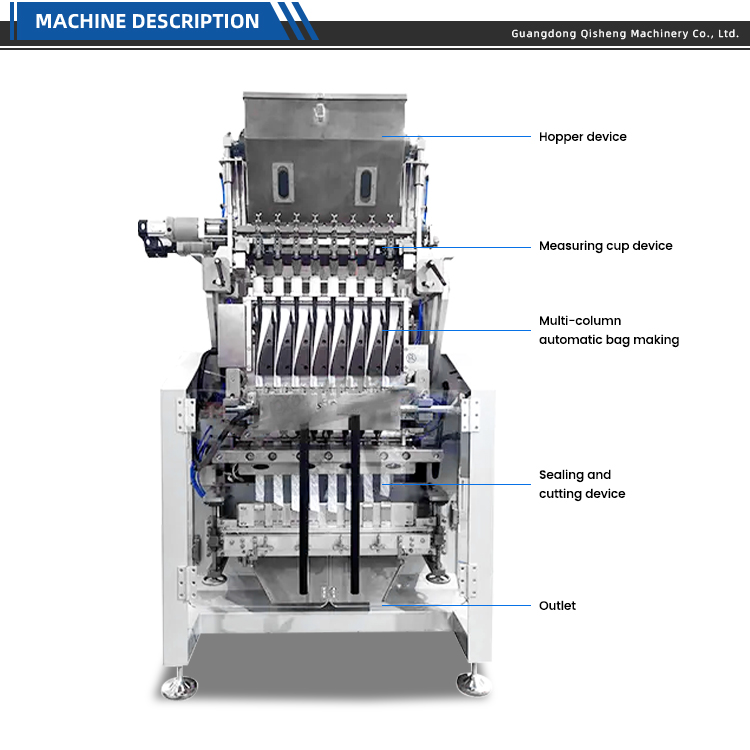

Details

Multi Lane Desiccant Packing Machine

| Lane number | 6-9 | Bag Shape | 3 Sides Sealing (Optional Back Sealing/Speacial bag type) | |

| Max roll film width(mm) | Max:640 | Bag length(mm) | 40-80 | |

| Bag width | 30-50mm | Machine weight | 1800KG | |

| Power | 220V 50/60Hz 4.5KW | Packing items | Powder,liquid | |

| Machine size | 1207*1901*1946(L*W*H) | Cutting speed(cut/min/lane) | Max 300mm | |

Product Feature

1.The powder multi lane packaging machine can customize 4-12 packaging channels according to different production capacity packaging needs to meet the packaging needs of different manufacturers. It comes in various packaging forms, including back sealing, three side sealing, four side sealing, or irregular bag shape. The shape of the packaged product is generally a flat bag with three or four sides sealed, and the four sides sealed shape requires a specially customized heat sealer body.

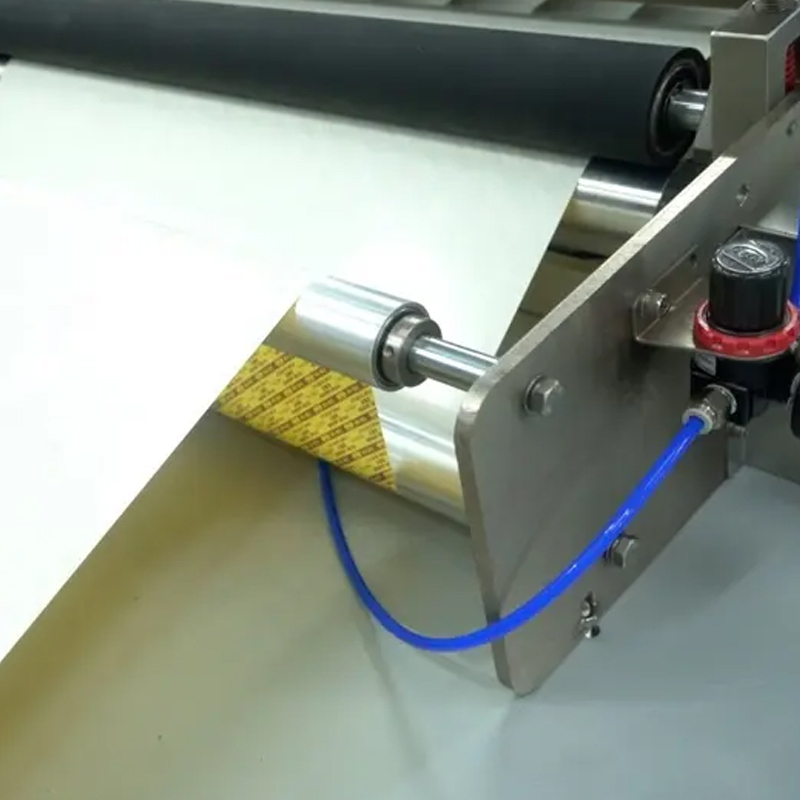

2.This machine has a series of functional features, including easy disassembly and assembly of film supply, flexible coding and bag length adjustment, simple disassembly and assembly of film dividing blades, CNC integrated molding, longitudinal sealing spring type force balance buffer, independent air pressure adjustment mold seal to ensure center position, high-precision ball screw and servo motor transmission, precise and convenient adjustment of the relative position of cutting and easy to tear edge knives with a handwheel type, and quick locking structure. In addition, it also has multiple sets of safety protection devices to prevent personnel injury and machine collision damage.

3.Technically, the powder multilane packaging machine adopts the most advanced microcomputer chip control internationally, combined with photoelectric eye tracking detection, to ensure accurate sealing and cutting within two packages. It is equipped with a dual CPU microcomputer control system and a 5-inch LCD display in both Chinese and English, providing a user-friendly operating interface. At the same time, high-precision stepper motors are used to ensure the accuracy of the cutting position of each packaging bag.

4.In terms of production efficiency, powder multi row packaging machines have significant advantages. Taking the small packaging of white sugar as an example, the speed can reach 55 bags/minute/column, while for powders such as flour, the average speed can reach 30 bags/channel per minute. Therefore, the 4-12 channels are 120-360 bags/minute, greatly improving production efficiency.

Overall, the powder multi lane packaging machine has the characteristics of low manufacturing cost, high production efficiency, high precision, and high degree of automation. It can also achieve the entire process of automatic measurement, filling, bag making, sealing, and forming of powder materials. According to the characteristics of the materials and product packaging requirements, suitable packaging bag materials and sealing methods can be selected to ensure complete packaging and beautiful appearance. At the same time, advanced electrical control and pneumatic drive technology are adopted, which can automatically detect the flow rate of materials and the size of packaging bags, avoid waste and loss, and ensure the accuracy and consistency of packaging. In addition, it also has fault detection and alarm functions to ensure the stable operation of equipment and the safety of personnel and equipment.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)