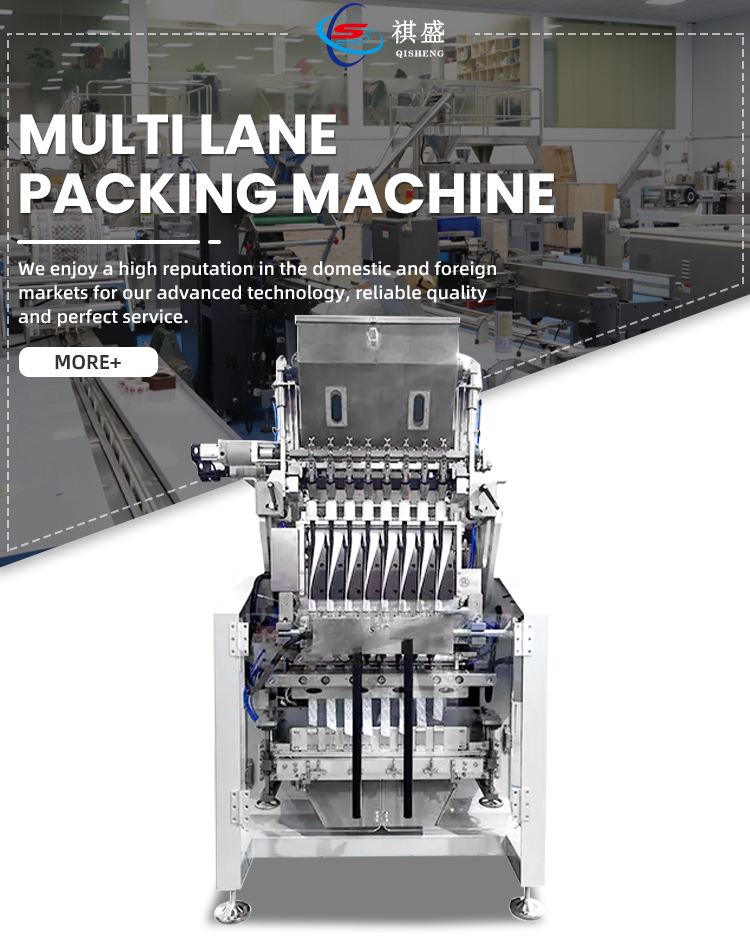

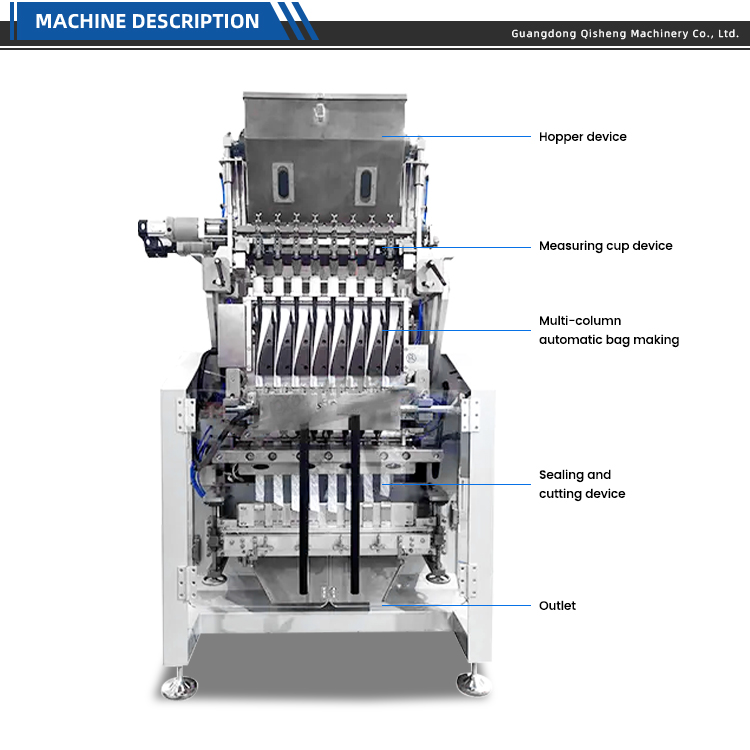

Sauce Multi Lane Sachet Packaging Machine

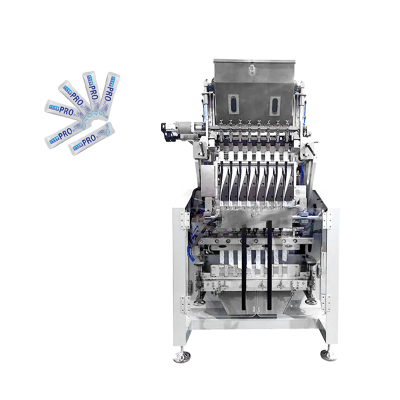

This Sauce Multi Lane Sachet Packaging Machine is an automated production equipment designed specifically for small packaging products such as sauces and seasonings. Its design is compact and efficient, capable of handling multiple production lines simultaneously, significantly improving packaging efficiency and reducing production costs.

Details

Multi Lane Desiccant Packing Machine

| Lane number | 6-9 | Bag Shape | 3 Sides Sealing (Optional Back Sealing/Speacial bag type) | |

| Max roll film width(mm) | Max:640 | Bag length(mm) | 40-80 | |

| Bag width | 30-50mm | Machine weight | 1800KG | |

| Power | 220V 50/60Hz 4.5KW | Packing items | Powder,liquid | |

| Machine size | 1207*1901*1946(L*W*H) | Cutting speed(cut/min/lane) | Max 300mm | |

Product Feature

Appearance and Structure:

The main body of the Sauce Multi Lane Sachet Packaging Machine is made of stainless steel or corrosion-resistant materials, ensuring the hygiene and durability of the equipment. There are multiple independent packaging positions (rows) above the body, each row is equipped with a precise measuring system and sealing device, ensuring that each sauce packet can be accurately filled and perfectly sealed. These rankings are arranged in multiple columns, making the entire packaging process compact and orderly, greatly improving space utilization.

Working principle:

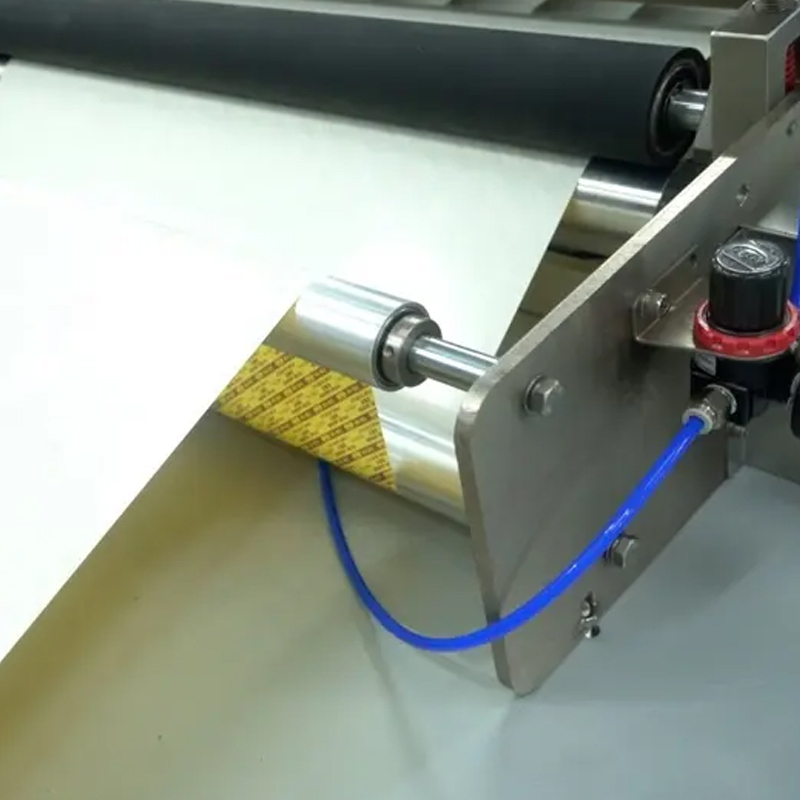

During the operation, the pre prepared sauce (such as the yellow granular substance shown in the picture, which may represent a certain seasoning sauce) is transported to the measuring system at each packaging position. The measuring system precisely controls the filling amount of each small package based on preset parameters to ensure product consistency. Subsequently, the sealing device quickly seals the filled sauce package to prevent leakage and contamination.

Applicability and advantages:

Sauce Multi Lane Sachet Packaging Machine is widely used in various industries such as seasonings, sauces, snacks, etc. Its multi column design greatly improves packaging efficiency, making it suitable for large-scale and batch production needs. At the same time, the device has high flexibility and adjustability, which can easily adapt to packaging bags of different specifications and materials, as well as the packaging needs of various sauce products. In addition, the equipment is equipped with an intelligent control system and fault alarm function, ensuring the stability and reliability of the production process.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)