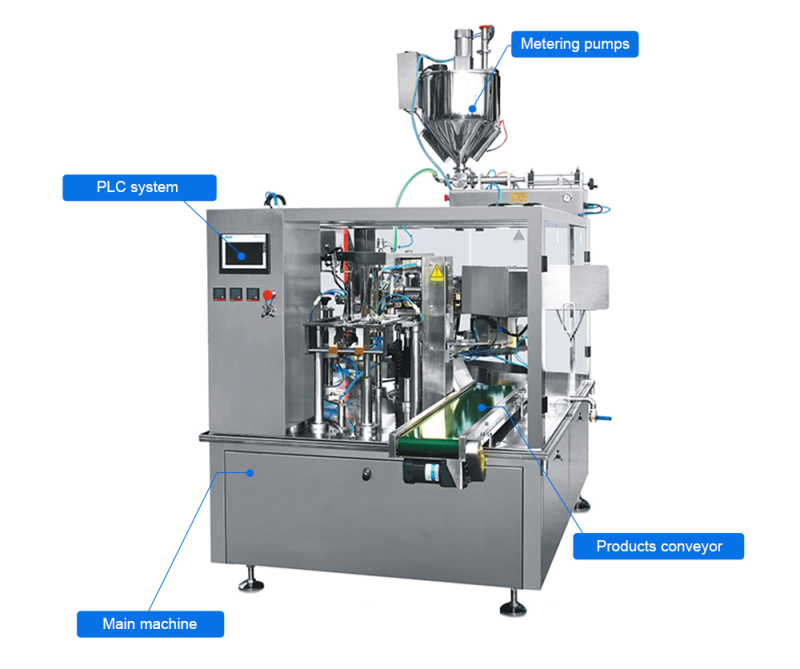

Sauce Doypack Pouch Machine

The sauce premade bag packaging machine is an indispensable part of modern sauce production lines. It can achieve efficient, hygienic, and safe packaging, providing great convenience for food enterprises.

Details

Sauce Doypack Pouch Machine

| Bag size | L<380mm,W<260mm | Weight range | MAX1200g/1200ml | |

| Bag type | Stand-up bag, zipper bag, doypack,flat bottom bag etc | Functions | Filling,Labeling,Sealing | |

| Speed | 20-50bags/min | Machine weight | 1200KG | |

| Power | 380V 2.5KW | Air consumption | 0.6-0.8m³/min | |

| Machine size | (L)2500mm×(w)1450mm×(H)700mm | Film width | Max 260mm | |

| Machine material | Stainless steel 304/316L for option | Total hight | 2.05m | |

The sauce premade bag packaging machine is a specialized equipment for packaging food materials such as sauces. It can automatically complete a series of operations such as bag picking, unfolding, printing production date and batch number, loading, vacuum packaging, etc. for prefabricated bags, thereby achieving automated packaging, greatly improving production efficiency, and reducing labor costs.

This device adopts an advanced PLC servo motor control system, combined with a touch screen and human-machine control page, making operation simple and fast. At the same time, it has the function of variable frequency speed regulation, which can freely adjust the packaging production speed within a certain range. The sauce premade bag packing machine is made of stainless steel, with a compact structure, beautiful and elegant appearance, and complies with GMP standards, ensuring the hygiene and safety of food packaging.

In addition, the design of the sauce doypack pouch machine takes into account energy conservation and environmental protection. For example, some components use imported engineering plastics, which do not require refueling and reduce material pollution; The liquid packaging machine adopts an oil-free vacuum pump to avoid pollution in the production environment; It also adopts waterproof design, making the equipment easy to clean, reducing the difficulty of cleaning, and improving the service life of the machine.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)