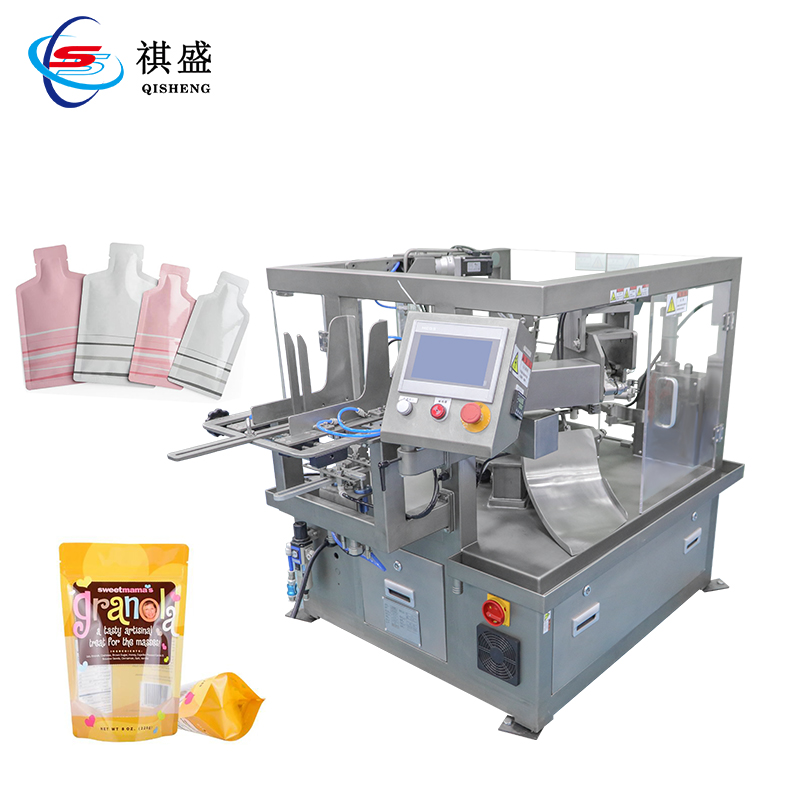

Automatic Six Station Premade Pouch Bag Packaging Machine

The Six Station Premade Pouch Bag Packaging Machine is an automated vertical packaging system designed for high-efficiency pouch filling and sealing operations. Featuring six synchronized working stations, this equipment ensures continuous production flow with enhanced precision and reliability.

Details

Six Station Premade Pouch Bag Packaging Machine

Bag size | L<380mm,W<180mm | Weight range | MAX2500g/2500ml | |

Bag type | Stand-up bag, zipper bag, doypack,flat bottom bag etc | Functions | Filling,Labeling,Sealing | |

Speed | 20-60bags/min | Machine weight | 750KG | |

Power | 380V 2.5KW | Air consumption | 0.6-0.8m³/min | |

Machine size | (L)2500mm×(w)1450mm×(H)700mm | Film width | Max 260mm | |

Machine material | Stainless steel 304/316L for option | Total hight | 2.05m | |

Key Features:

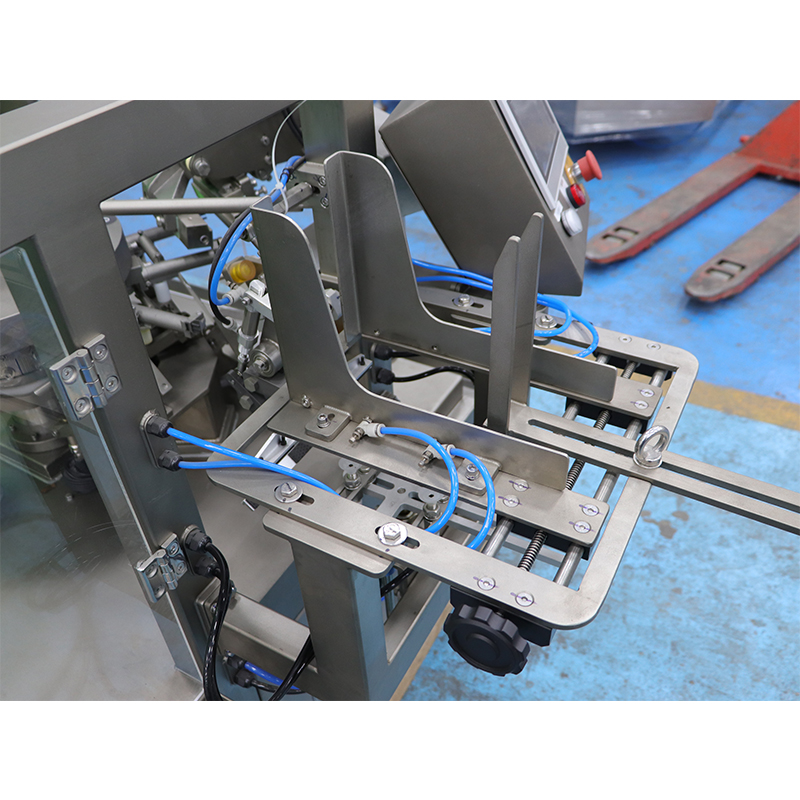

Multi-Station Design

Bag pickup & positioning

Bag opening & inflation

Material filling (primary product)

Optional secondary filling (auxiliary items)

Gas flushing (for modified atmosphere packaging)

Heat sealing & product discharge

Six independent workstations sequentially perform:

Advanced Automation

Integrated servo control system

Photoelectric bag positioning sensors

Automatic bag feeding mechanism

Fault detection with emergency stop function

Technical Specifications

Capacity: 30-60 bags/min (depending on product)

Bag size range: 50-300mm (W) × 70-400mm (H)

Compatible materials: PE, CPP, AL foil, stand-up pouches

Power: 380V/50Hz (3-phase)

Air pressure: 0.6-0.8MPa

Flexible Applications

Food: snacks, powders, liquids

Pharmaceuticals: sachets, medical products

Chemicals: detergents, agricultural products

Consumer goods: hardware, stationery

Technical Advantages

Dual safety protection (mechanical + electrical)

CIP (Clean-in-Place) compatible design

HMI touchscreen interface with recipe storage

Quick-change tooling for different pouch styles

Compliant with CE/GMP standards

Optional Configurations:

Multi-head weigher integration

Nitrogen/Vacuum packaging module

Date coding system

Metal detection

Bag alignment conveyor

This modular packaging solution combines speed with operational flexibility, making it ideal for medium-to-large scale production lines requiring frequent product changeovers while maintaining strict hygiene standards.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)