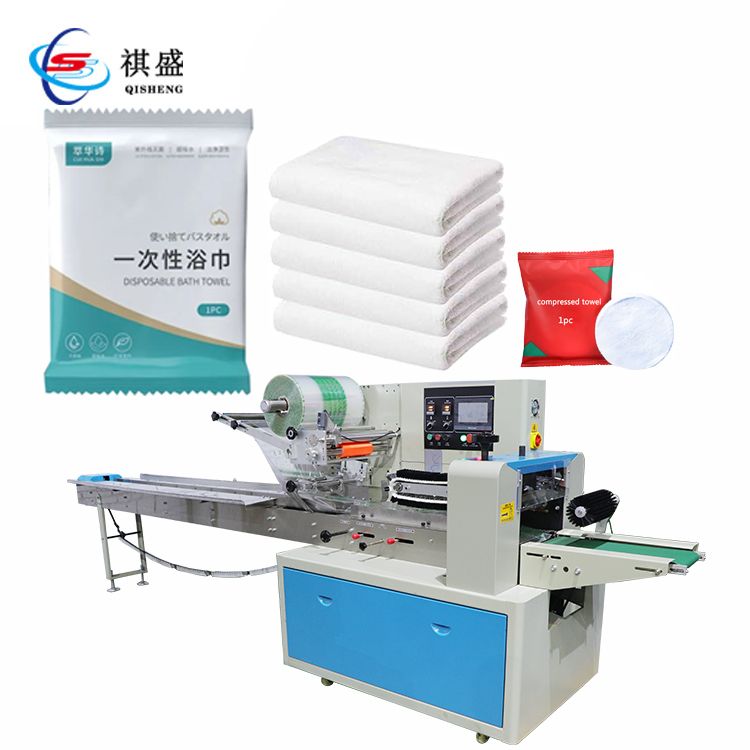

Disposable towel flow wrap packaging machine

The Disposable towel flow wrap packaging machine is widely used in industries such as hotels, guesthouses, tourism, and healthcare that require a large amount of disposable sanitary products. Its efficient and automated packaging process can significantly improve production efficiency, reduce labor costs, while ensuring consistency and stability in packaging quality. In addition, the Disposable towel flow wrap packaging machine also has flexibility and scalability, which can easily adapt to the packaging needs of disposable bath towels of different specifications and materials.

Details

Disposable towel flow wrap packaging machine

| Bag width | 30-110mm | Weight range | 30-1000g | |

| Film material | OPP/CPP.OPP/PE/PET | Functions | Filling,Labeling,Sealing | |

| Speed | Max 230bags/min | Machine weight | 500KG | |

| Power | 220V 2.4KW | Packing items | Noodle, spaghetti,rice noodle etc | |

| Machine size | 3770*720*1420mm(L*W*H) | Film width | Max 250mm | |

| Machine material | Stainless steel 304/316L for option | |||

Description:

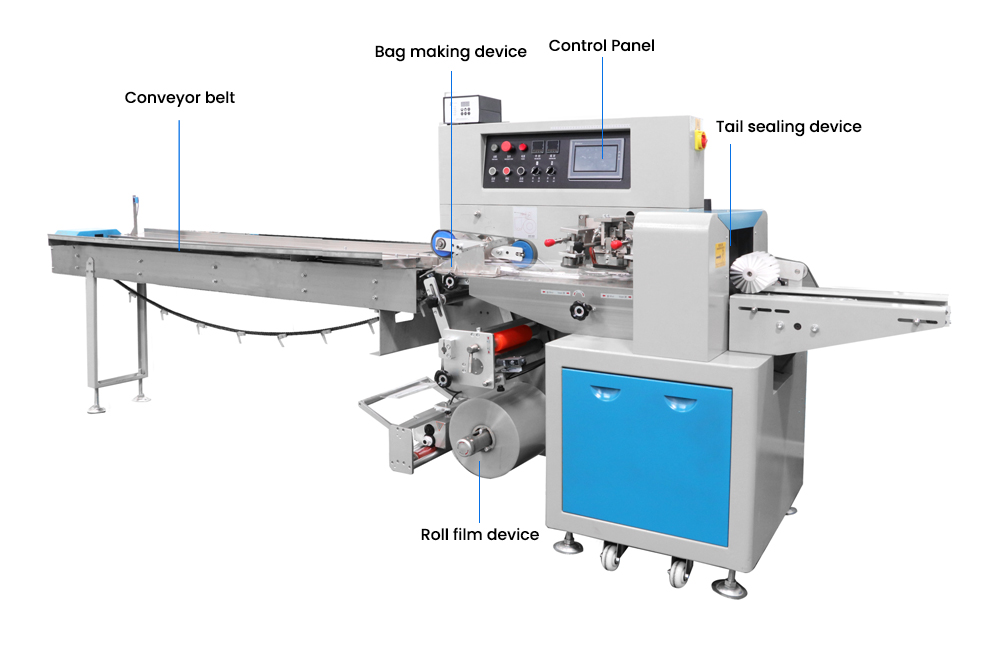

Appearance and Structure:

The Disposable towel flow wrap packaging machine is made of sturdy and durable materials to ensure stability and reliability during long-term operation. Its overall design is compact and integrates advanced automation control systems, which can accurately complete the entire packaging process from product input to finished product output. The Disposable towel flow wrap packaging machine is equipped with clear digital display screens and control panels, allowing operators to easily set and adjust packaging parameters such as packaging speed, temperature, size, etc., to accommodate disposable bath towels of different specifications and materials.

Working principle:

During the packaging process, pre prepared disposable bath towels are fed into the feeding port of the packaging machine. The conveyor belt inside the machine smoothly transports these bath towels to the packaging position. Subsequently, the packaging film is automatically unfolded and wrapped around the towel. Through a heat sealing device, the packaging film is rapidly and uniformly heated and sealed, forming a sealed, easy to carry and store pillow style packaging.

Packaging effect:

After packaging is completed, the finished disposable bath towel pillow bags will be neatly arranged at the discharge port or conveyor belt, ready for subsequent packing, stacking, or distribution. These pillow style packaging not only protect the cleanliness and hygiene of bath towels, but also enhance the product's aesthetics and market competitiveness.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)