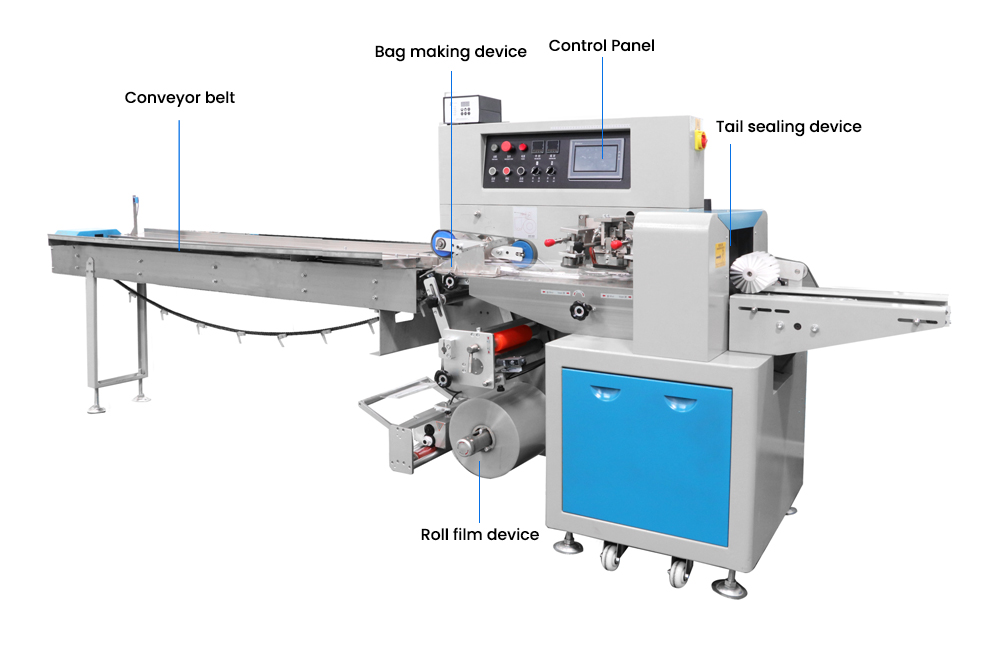

Instant Noodle Packing Machine

The instant noodle flow wrap packaging machine is a continuous packaging machine specifically designed for instant noodle packaging. This packaging machine has strong packaging capabilities, which is not only suitable for packaging non branded packaging materials, but also for high-speed packaging of roll materials with pre printed trademark patterns.

Details

Instant Noodle Packing Machine

| Bag width | 30-110mm | Weight range | 30-1000g | |

| Film material | OPP/CPP.OPP/PE/PET | Functions | Filling,Labeling,Sealing | |

| Speed | Max 230bags/min | Machine weight | 500KG | |

| Power | 220V 2.4KW | Packing items | Noodle, spaghetti,rice noodle etc | |

| Machine size | 3770*720*1420mm(L*W*H) | Film width | Max 250mm | |

| Machine material | Stainless steel 304/316L for option | |||

Description:

1.During the packaging process, the horizontal flow wrap packaging machine uses a delivery device to deliver instant noodles and other items to the roll or film inlet, and forms cylindrical packaging through the bag making machine. Then, the entire packaging process is completed through processes such as heat sealing, air release (vacuum packaging) or air supply (inflatable packaging), and cutting. This packaging method is particularly suitable for packaging individual or integrated items with relatively fixed shapes such as blocks, strips, and balls.

2.The horizontal flow wrap packaging machine also has a series of performance characteristics, such as positioning shutdown function, which can effectively prevent film scalding during shutdown; The induction anti cutting function can completely solve the cutting phenomenon caused by material misalignment and improve the packaging yield; Positive direction tracking function improves tracking accuracy, ensures cutting accuracy, and avoids packaging material waste; Product parameter memory function, when replacing products with different packaging, touch the display screen for one click adjustment, convenient and fast, and easy to understand operation by employees; Fully automatic induction of incoming material startup, no material shutdown, no empty package phenomenon, material level deviation and misalignment end sealing without cutting; And with a wide range of packaging, multi specification products can be completed on one device, saving unnecessary expenses.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)