Horizontal Instant Noodle Packaging Machine: Enhancing Efficiency in Noodle Packaging

Horizontal Instant Noodle Packaging Machine: Enhancing Efficiency in Noodle Packaging

Introduction

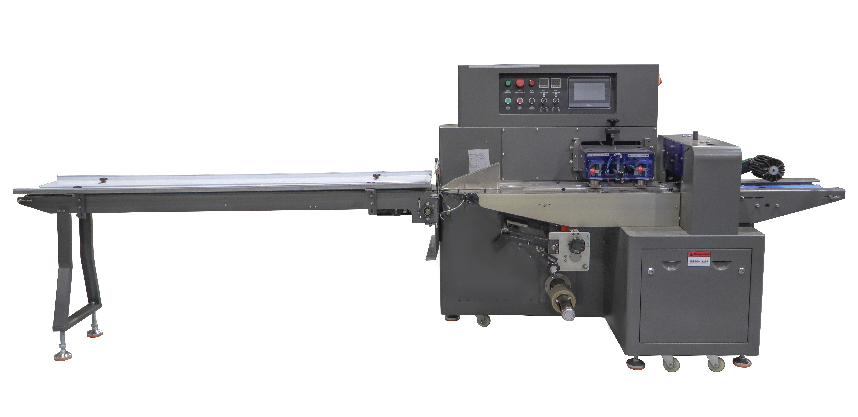

Instant noodles are a staple in the global food industry, requiring fast, reliable, and hygienic packaging solutions to meet consumer demand. A horizontal instant noodle packaging machine offers high-speed, automated, and precise packaging, ensuring freshness and extending product shelf life. This article explores the key features, working process, and advantages of using a horizontal packaging machine for instant noodles.

Key Features

1. High-Speed Operation

Capable of packaging 120 packs per minute, ensuring maximum production output.

Optimized for continuous operation, reducing downtime and increasing efficiency.

2. Automated Packaging Process

Integrates feeding, wrapping, sealing, and cutting into a streamlined process.

Reduces manual labor, minimizing errors and improving consistency.

3. Adjustable Configurations

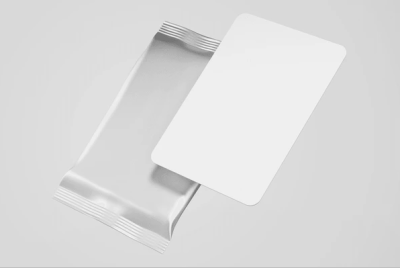

Accommodates different packaging styles, including pillow packs and multi-pack formats.

Customizable settings for sealing temperature, film tension, and package size.

4. Precision Sealing and Cutting

Uses advanced temperature control and cutting mechanisms to ensure a secure, airtight seal.

Prevents contamination, maintains product integrity, and extends shelf life.

5. User-Friendly Interface

Touchscreen control panel with intuitive operation and real-time monitoring.

Allows for quick adjustments and easy maintenance.

6. Hygienic and Durable Design

Made of food-grade stainless steel, complying with FDA and CE standards.

Ensures cleanliness and long-term reliability in food production environments.

Working Principle

The horizontal instant noodle packaging machine follows a simple yet efficient process:

1. Film Feeding

The machine automatically unwinds a roll of packaging film, ensuring continuous operation.

2. Noodle Cake and Seasoning Packet Loading

Noodle cakes and accompanying seasoning sachets are precisely fed onto a conveyor belt.

Automated alignment systems ensure accurate positioning before packaging.

3. Wrapping and Sealing

The packaging film forms around the noodle cakes.

Heat sealing technology creates an airtight and tamper-proof seal.

4. Cutting and Discharge

After sealing, the film is cut into individual packages.

Finished packs are conveyed to the next stage of production for boxing or distribution.

Applications

Horizontal packaging machines are widely used in the food industry, particularly for:

Instant Noodles : Single-pack and multi-pack options for different market demands.

Ramen and Specialty Noodles: Customizable packaging for premium products.

Snack Foods: Similar packaging solutions for pasta, chips, and other dry food products.

![]()

Advantages of Horizontal Instant Noodle Packaging Machines

Increased Production Efficiency

High-speed automation reduces labor costs and enhances production rates.

Minimized Product Damage

Gentle handling ensures no breakage or crushing of the noodle cakes.

Extended Shelf Life

Airtight sealing prevents exposure to moisture, oxygen, and contaminants.

Consistent Packaging Quality

Uniform package sizes enhance brand consistency and market appeal.

Cost-Effective Operation

Reduces material waste and optimizes production efficiency, lowering costs.

Conclusion

A horizontal instant noodle packaging machine is an essential solution for food manufacturers looking to improve efficiency, product protection, and overall packaging quality. By automating the process and ensuring precision in sealing and cutting, this machine optimizes production while maintaining hygiene and freshness. Investing in a horizontal packaging system enhances productivity, reduces costs, and ensures that packaged instant noodles meet industry standards.

Get the latest price? We'll respond as soon as possible(within 12 hours)