- Home

- >

- Products

- >

- Multihead Weigher

- >

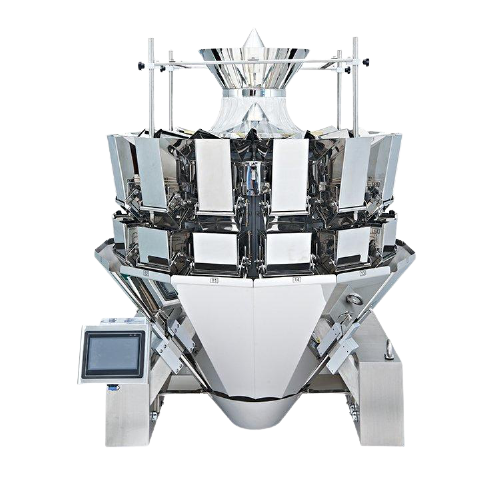

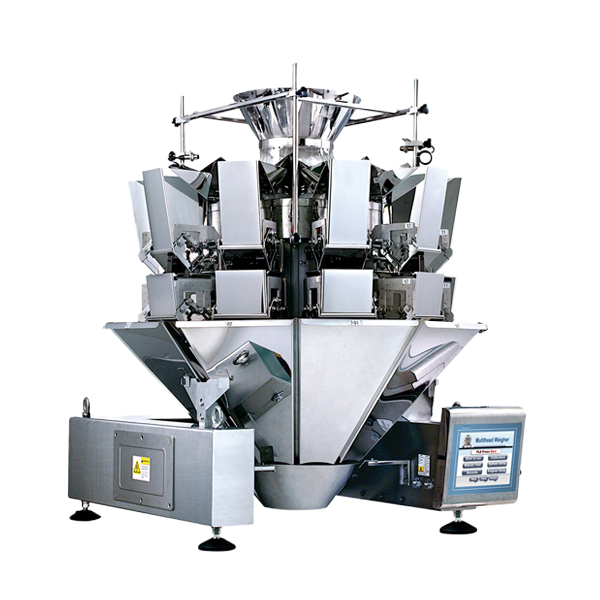

Multihead Weigher

Multihead weigher developed for precise and high-speed quantitative weighing packaging system. It is suitable for weighing grain, stick, slice, globose, irregular shape products such as candy, chocolate, jelly, pasta, melon seeds, roasted seeds, peanuts, pistachios, almonds, cashews, nuts, coffee bean, chips ,raisins, plum, cereals and other leisure foods, pet food, puffed food, vegetable, dehydrated vegetables ,fruits, sea food, frozen food, small hardware, etc.

Details

Multihead Weigher

Main Features

1.Special big machine designed for big size products.

2.Bigger hopper volume, stronger vibrator and larger opening doors.

3.Adjustable rotating topcone to dispense leaf products evenly.

4.New 4.0 generation software makes control easier and faster.

5.More models available including 10 heads, 14 heads and 16 heads.

6.Biggest volume 7.5L hopper for wider applications.

Description:

Multi head weigher, also known as multi head combination weigher or multi head screw feeder, is an automatic quantitative packaging equipment used in industries such as food, chemical, and pharmaceutical. It mainly consists of weighing system, control system, spiral feeding mechanism, material hopper, etc., and has the characteristics of high precision, high efficiency, and high stability.

The working principle of a multi head scale is to uniformly transport materials from the material hopper to the weighing system through a spiral feeding mechanism. The weighing system detects the weight of materials in real-time through sensors. When the preset value is reached, the control system will send a signal to stop the rotation of the screw feeding mechanism, thereby achieving accurate quantitative packaging. Multi head weighing can simultaneously control multiple weighing heads, achieving quantitative packaging of various different materials, improving production efficiency and packaging accuracy.

Multi head weigher have various advantages, such as small footprint, compact structure, easy operation, and easy maintenance. Meanwhile, it can also be customized according to different production needs, such as different weighing ranges and feeding methods, to meet the production needs of different industries.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)