Bubble Film Horizontal Packing Machine: Ideal Solution for Protective and Efficient Packaging

Bubble Film Horizontal Packing Machine: Ideal Solution for Protective and Efficient Packaging

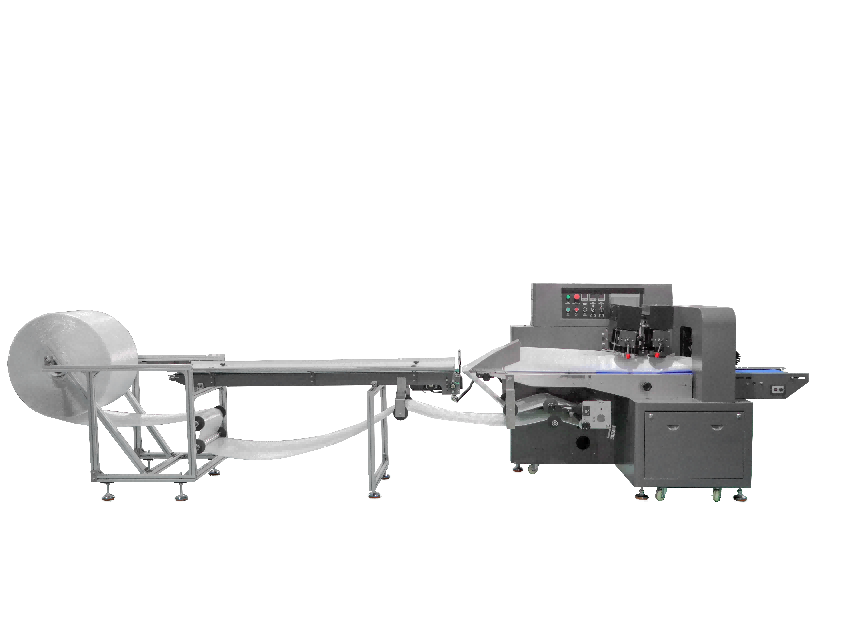

In industries where product protection during transportation and storage is critical, bubble film has become a preferred packaging material. The bubble film horizontal packing machine, designed specifically for wrapping products with air bubble film, ensures effective cushioning, high-efficiency packaging, and superior presentation. Unlike traditional horizontal packing machines, this equipment features a rear-mounted film roll (tail frame design) to accommodate the special properties of bubble film, ensuring smooth feeding and excellent packaging results.

This article explores the key features, working principle, and wide-ranging applications of the bubble film horizontal packing machine, highlighting why it is an indispensable tool for modern protective packaging.

Key Features

1.Tail Frame Film Loading

The bubble film is mounted at the rear of the machine, minimizing film tension and maintaining bubble integrity throughout the packaging process.

2.Specialized Film Feeding System

The machine is equipped with a reinforced and widened film-feeding path, ensuring the thick and flexible bubble film moves steadily without bursting bubbles or wrinkling.

3.Flexible Product Compatibility

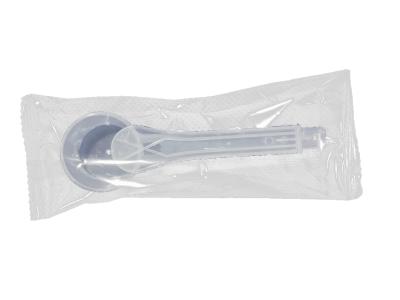

Suitable for packaging a variety of products including electronics, cosmetics, hardware parts, fragile items, and small household goods.

4.High-Efficiency Packing

Capable of continuous operation with minimal downtime, delivering neat and secure packages while improving production efficiency.

5.Advanced Sealing Technology

Equipped with high-precision temperature control systems and wide sealing jaws, ensuring strong, airtight seals without damaging the bubble structure.

Working Principle

1. Film Feeding:

Bubble film from the rear-mounted roll is automatically fed into the forming area, maintaining stability and preserving bubble integrity.

2. Product Infeed:

Products are placed onto the infeed conveyor and transported to the forming section.

3. Forming and Wrapping:

The film is wrapped around the product in a tubular shape through a forming collar, enveloping the item with cushioning protection.

4. Sealing and Cutting:

Horizontal and longitudinal sealing units seal the edges of the bubble film tightly, followed by cutting to create individual, neatly packaged items.

5. Finished Package Output:

Packaged products are discharged onto a collection conveyor, ready for boxing, labeling, or direct shipment.

Applications

The bubble film horizontal packing machine is ideal for:

Electronics Packaging (mobile phones, tablets, computer parts)

Cosmetic Products (glass bottles, fragile containers)

Hardware Items (tools, fittings, components)

Household Goods (ceramics, artworks, souvenirs)

Medical Supplies (delicate instruments, samples)

Advantages of Using a Bubble Film Packing Machine

1.Enhanced Product Protection

Cushioning bubble layer absorbs shocks and prevents damage during handling and transport.

2.Increased Packaging Efficiency

Fully automated process significantly boosts packing speed and reduces manual labor costs.

3.Improved Presentation

Neat and consistent packaging enhances the product's market appeal and brand image.

4.Reduced Material Waste

Precise film control minimizes wastage of bubble film, lowering operational costs.

5.Easy Adaptability

Quick adjustment for various product sizes and packaging requirements, enhancing flexibility for diversified production.

Conclusion

The bubble film horizontal packing machine is an essential investment for manufacturers aiming to provide top-quality, protective packaging solutions. Its specialized design, incorporating a rear film mounting system and optimized bubble handling technology, ensures smooth operation, superior packaging performance, and maximum product protection. Whether you are packaging delicate electronics or fragile household items, this machine offers the perfect blend of efficiency, reliability, and professionalism.

Get the latest price? We'll respond as soon as possible(within 12 hours)